The Ultimate Guide to MRO Inventory Optimization

Discover how effective MRO management can drive cost savings, operational efficiency, and long-term success. Explore key strategies and best practices that elevate your approach to MRO.

Mastering MRO Management

MRO Data Cleansing

The Role of Data Cleansing in MRO Optimization

Accurate data is the cornerstone of MRO inventory optimization. Without clean, reliable data, your entire MRO strategy can falter, leading to increased costs, inefficiencies, and operational disruptions.

Common data issues in MRO inventory management include duplicate entries, outdated information, and inconsistent naming conventions. These issues can lead to overstocking, stockouts, and a general lack of trust in the data, making it difficult to optimize inventory levels and meet production demands efficiently. By addressing these data issues head-on — as with purpose-built MRO inventory optimization software — you can lay a solid foundation for a more streamlined and effective MRO inventory management system.

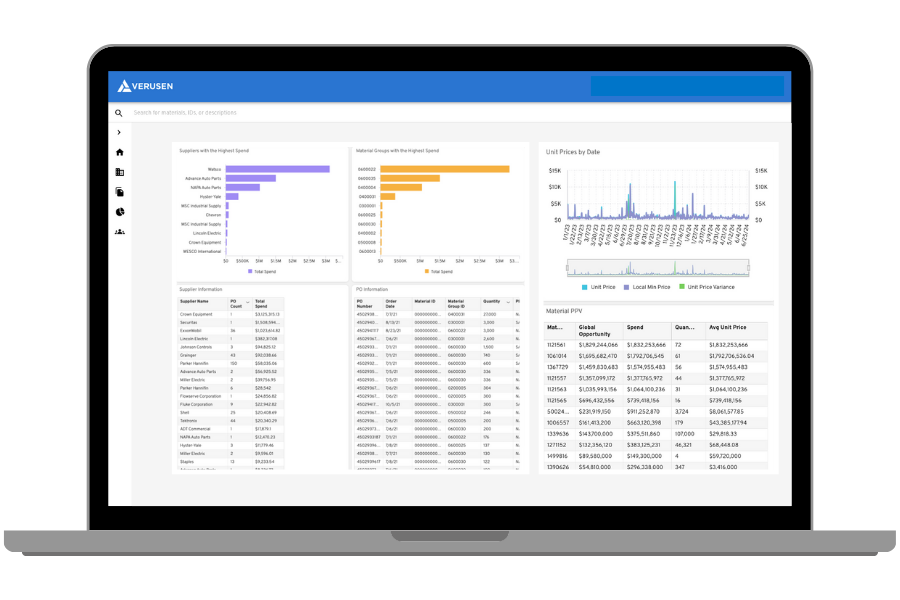

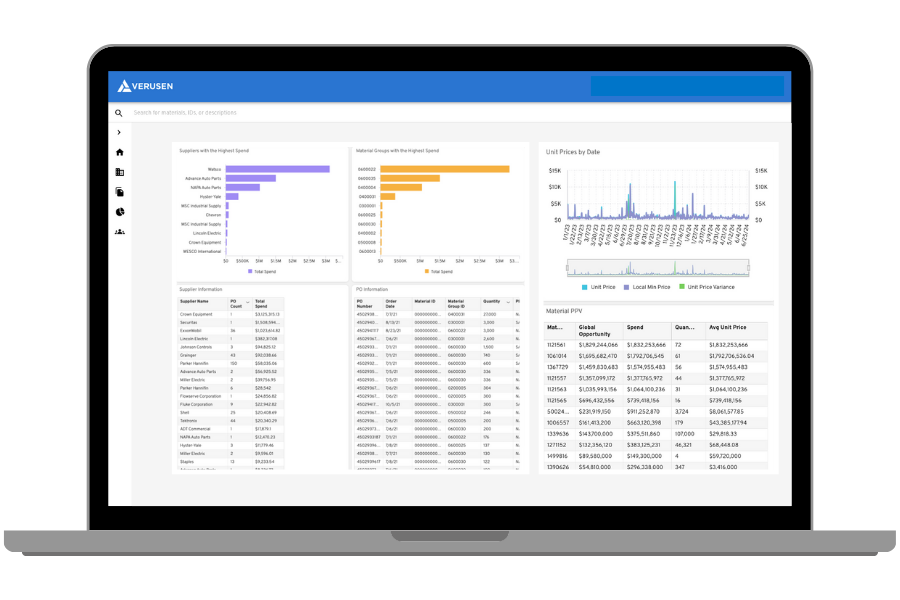

Traditional data cleansing projects are often seen as the go-to solution for tackling dirty data issues, but they tend to be time-consuming, expensive, and frequently fall short of delivering meaningful value. Data cleansing involves identifying and rectifying inaccuracies, inconsistencies, and duplications within your data sets to ensure you have a clear and precise inventory picture. With advancements in AI, organizations can now leverage existing MRO inventory data in its current form to address gaps and drive desired outcomes without the need for extensive data cleanup efforts.

Steps to Effective MRO Data Cleansing

Those embarking on a traditional data cleanse (despite AI solutions having rendered them obsolete) should follow the three basic steps outlined below.

Data Assessment and Auditing

Start by conducting a comprehensive audit of your current MRO data. Your assessment should involve identifying data sources, assessing data quality, and pinpointing areas that require cleansing. Regular audits help ensure ongoing reliability by enabling your organization to maintain data accuracy over time.

Standardizing and Normalizing Data

Standardization involves ensuring that data entries follow a consistent format, such as using the same unit measurements or naming conventions across all records. Establishing consistent data treatment practices helps eliminate redundancies and inconsistencies, creating a cohesive and uniform data set that is easier to manage and analyze.

Implementing Data Governance Practices

Establishing robust data governance practices ensures that data management is systematic and ongoing. This includes defining roles and responsibilities for data management, setting data quality standards, and implementing processes for regular data review and updates.

Tools and Technologies for MRO Data Cleansing

Utilizing advanced tools and technologies is crucial for achieving and maintaining clean MRO data. These include:

Software Solutions for Data Cleansing

Leveraging specialized software tools can significantly streamline the data cleansing process. These tools are designed to identify and correct errors, remove duplicates, and standardize data formats automatically. By integrating such tools into your MRO inventory management system, you can enhance data accuracy and consistency.

Integration With Existing ERP Systems

Effective data cleansing tools should seamlessly integrate with your existing ERP systems. This integration allows for real-time data updates and ensures that cleansed data is consistently used across all business processes, enhancing overall efficiency and accuracy while allowing for effective MRO inventory optimization.

Benefits of Clean MRO Data

Clean MRO data is essential for maximizing operational efficiency and driving cost savings across your organization. Consider these benefits of maintaining clean MRO data.

Improved Inventory Accuracy

Clean data ensures that inventory records accurately reflect actual stock levels, reducing the risk of overstocking or stockouts. This accuracy helps with maintaining optimal inventory levels and minimizing costs associated with excess inventory and production downtime.

Enhanced Decision-Making Capabilities

With accurate data, decision-makers can rely on solid information to guide…

Maximize Inventory Accuracy

Effective MRO management is essential for maintaining operational efficiency and reducing costs. Explore our comprehensive guide to learn best practices and strategies that drive results. Use the links below to dive into each critical aspect of MRO inventory optimization.

MRO Data Cleansing

MRO Sourcing

Critical Spare Parts Management

Tail Spend Management

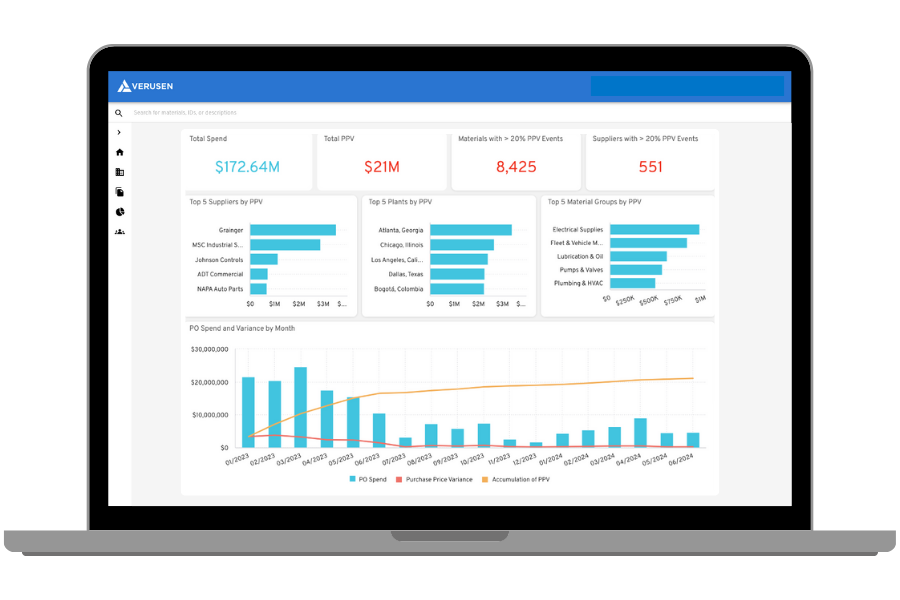

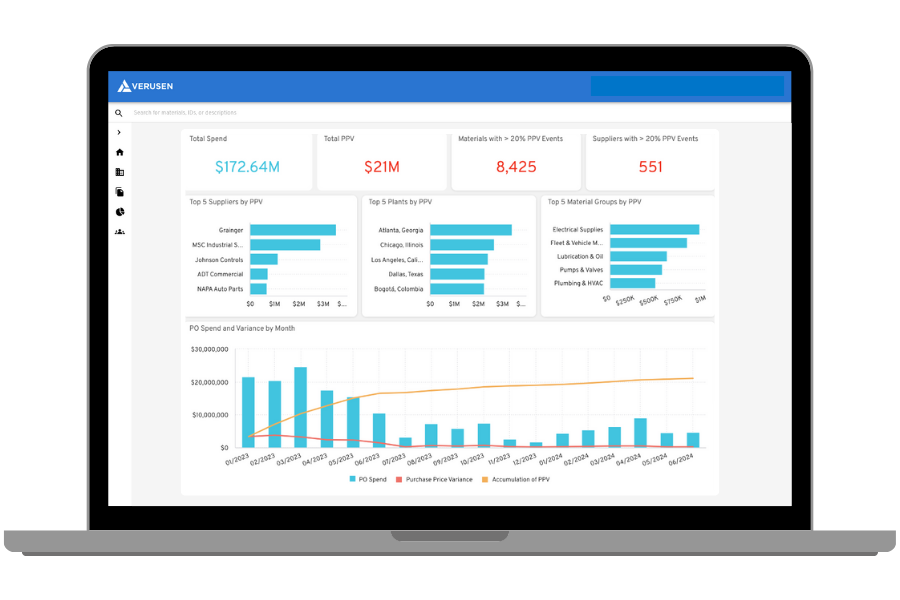

MRO Sourcing

Understanding MRO Sourcing

MRO sourcing is a critical aspect of any organization’s supply chain management. It involves the procurement of essential spare parts, tools, and supplies necessary to maintain equipment (whether OEM, OBM, or otherwise) and facilities. While it may not always receive the same level of attention as direct material sourcing, the significance of MRO sourcing cannot be overstated. Effective MRO sourcing is key to reducing downtime, maintaining operational efficiency, and managing costs.

However, MRO sourcing is not without its challenges. The decentralized nature of MRO purchasing, the sheer variety of items needed, and the difficulty in predicting demand can create complexity and inefficiency. Additionally, organizations often face issues such as maverick spending, supplier inconsistency, and lack of visibility into overall MRO inventory. These challenges can lead to overstocking, stockouts, and inflated procurement costs, ultimately impacting the bottom line.

Strategies for Effective MRO Sourcing

To overcome these challenges, organizations must adopt strategic approaches to MRO sourcing that align with their broader business goals.

Developing a Strategic Sourcing Plan

The foundation of effective MRO sourcing lies in a well-defined strategic sourcing plan. This involves a thorough analysis of MRO spend, identifying critical items, and determining the best procurement methods. A strategic plan should prioritize high-impact items and leverage data to forecast demand accurately, which enables better inventory management and procurement decisions.

Supplier Evaluation and Selection

Choosing the right suppliers is crucial for MRO inventory optimization. Organizations should evaluate suppliers based on criteria such as:

- Reliability

- Quality

- Cost

- Responsiveness

- Delivery performance

Building strong relationships with suppliers can also lead to long-term benefits, such as better pricing, faster response times, and access to innovative solutions. Regular supplier audits and performance reviews are essential to maintaining high standards.

Negotiating Contracts and Terms

Effective negotiation is key to securing favorable terms and conditions in MRO sourcing contracts. This includes negotiating prices, delivery schedules, and payment terms, as well as establishing clear expectations for quality and service levels. By consolidating spend and leveraging volume purchases, organizations can negotiate more favorable terms and reduce procurement costs. To ensure supply chain resilience, it’s also important to include clauses that address potential disruptions.

Benefits of Optimized MRO Sourcing

Optimized MRO sourcing offers a multitude of benefits, including:

Cost Savings and Budget Management

One of the most immediate advantages of effective MRO sourcing is the potential for significant cost savings. By streamlining procurement processes, negotiating better terms, and reducing maverick spending, organizations can better manage their MRO budgets and allocate resources more efficiently.

Enhanced Supplier Relationships

Optimized MRO sourcing fosters stronger, more collaborative relationships with suppliers. When suppliers are viewed as strategic partners rather than mere vendors, they are more likely to offer value-added services, share innovations, and respond more effectively to an organization’s needs. These relationships can lead to improved service levels and greater operational efficiency.

Improved Supply Chain Resilience

In today’s volatile business environment, supply chain resilience is more important than ever. An effective MRO sourcing strategy helps organizations mitigate risks by ensuring a reliable supply of critical items, even in the face of disruptions. This resilience not only minimizes the risk of downtime but also supports continuous operations.

Optimize MRO Procurement

Effective MRO management is essential for maintaining operational efficiency and reducing costs. Explore our comprehensive guide to learn best practices and strategies that drive results. Use the links below to dive into each critical aspect of MRO inventory optimization.

MRO Data Cleansing

MRO Sourcing

Critical Spare Parts Management

Tail Spend Management

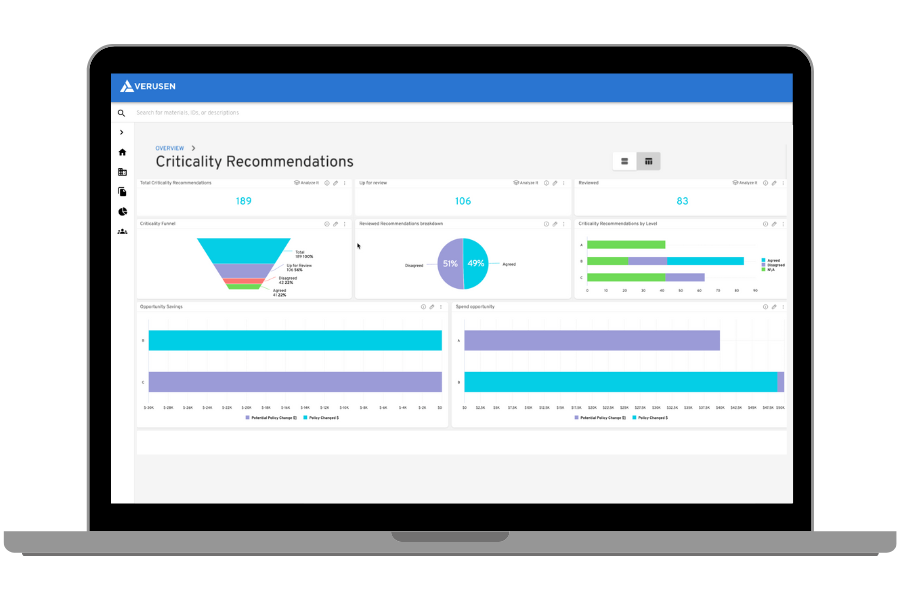

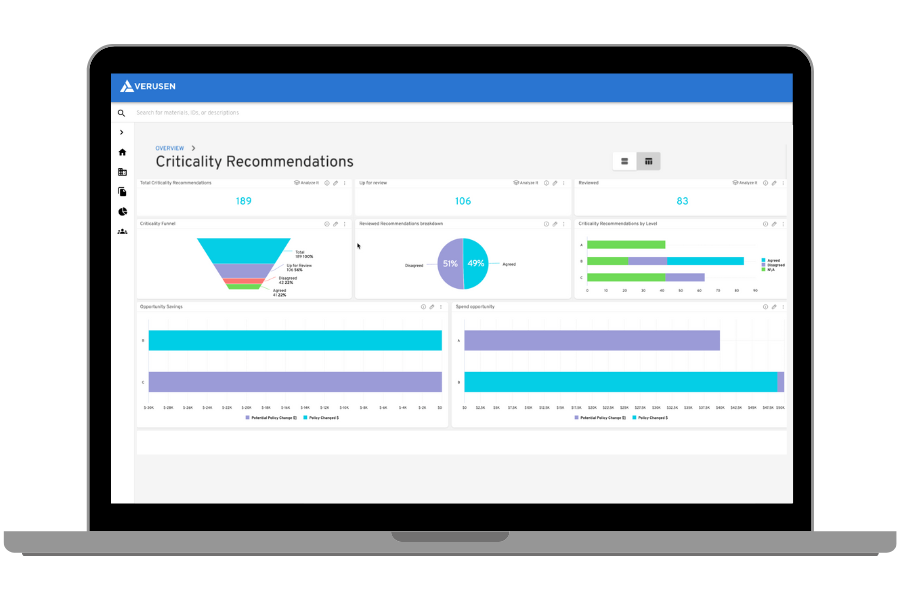

Critical Spare Parts Management

Importance of Critical Spare Parts Management

Critical spare parts are the backbone of any organization’s maintenance and operations strategy. These are the essential components that, if unavailable when needed, could cause significant disruptions, prolonged downtime, or even catastrophic equipment failures. The significance of managing these parts effectively cannot be overstated, as they directly impact the reliability, availability, and performance of key assets.

In many industries, a shortage of critical spare parts can lead to unplanned production halts, loss of revenue, and increased maintenance costs. Without a well-defined approach to managing these vital components, organizations are left vulnerable to reactive maintenance strategies, which are not only inefficient but also costly. Proper management of critical spare parts is, therefore, essential for maintaining operational continuity, minimizing downtime, and ensuring that maintenance teams can respond swiftly to equipment failures.

Strategies for Managing Critical Spare Parts

Effectively managing critical spare parts requires a combination of strategic planning, advanced techniques, and the integration of modern technologies.

Identifying Critical Spare Parts

The first step in managing critical spare parts is accurately identifying which parts are truly critical. This involves assessing the impact of each component on the overall operation, considering factors such as equipment criticality, failure rates, and lead times. A thorough risk analysis helps prioritize which parts must be readily available to prevent disruptions. Organizations can focus resources on maintaining the most essential items by categorizing parts based on their criticality.

Implementing Inventory Optimization Techniques

Once critical parts have been identified, the next step is to optimize their inventory levels. This includes balancing the costs of holding inventory with the risks of stockouts. Techniques such as ABC analysis, economic order quantity (EOQ), and safety stock calculations can help determine the optimal inventory levels for critical spare parts. Additionally, organizations should regularly review and adjust these levels based on changes in demand, lead times, and maintenance schedules to ensure that inventory remains aligned with operational needs.

Using Predictive Maintenance and Demand Forecasting

Predictive maintenance and demand forecasting technologies are powerful tools in managing critical spare parts. By leveraging real-time data and predictive analytics, organizations can anticipate when specific parts are likely to fail and plan their procurement and maintenance activities accordingly.

When combined with accurate demand forecasting, predictive maintenance helps organizations move away from reactive maintenance strategies, resulting in more efficient use of resources and improved equipment uptime. This proactive approach not only reduces the likelihood of unplanned downtime but also ensures that parts are available precisely when needed — a critical objective of MRO inventory optimization.

Benefits of Effective Spare Parts Management

The advantages of implementing a robust critical spare parts management system are significant and far-reaching. They include:

Reduced Downtime and Maintenance Costs

One of the most immediate benefits of effective spare parts management is the reduction in downtime and associated maintenance costs. By ensuring that critical parts are available when needed, organizations can minimize the time required for repairs and maintenance, leading to faster recovery times and lower costs. This approach also reduces the need for emergency procurement, which is often more expensive and less reliable.

Increased Equipment Reliability and Uptime

Effective management of critical spare parts directly contributes to improved equipment reliability and uptime. With the right parts on hand, maintenance teams can perform timely repairs and preventive maintenance to ensure that equipment operates at peak performance. This not only extends the lifespan of assets but also enhances overall productivity, as equipment is less likely to experience unexpected failures.

Enhanced Overall Operational Efficiency

A well-executed spare parts management strategy enhances operational efficiency by streamlining maintenance processes and reducing the likelihood of operational disruptions. With optimized inventory levels and predictive maintenance in place, organizations can allocate resources more effectively, reduce waste, and improve the coordination between teams. This leads to smoother, more efficient operations and a stronger bottom line.

Reduce Downtime Risks

Effective MRO management is essential for maintaining operational efficiency and reducing costs. Explore our comprehensive guide to learn best practices and strategies that drive results. Use the links below to dive into each critical aspect of MRO inventory optimization.

MRO Data Cleansing

MRO Sourcing

Critical Spare Parts Management

Tail Spend Management

Tail Spend Management

Understanding Tail Spend in MRO

Tail spend refers to the small, often overlooked purchases that collectively account for a significant portion of an organization’s total spend. In the context of MRO, tail spend typically includes low-value, non-strategic items that are purchased infrequently or in small quantities. Despite their individual insignificance, these purchases can add up to a substantial amount — often comprising 20% of the total spend while involving up to 80% of suppliers.

Challenges Associated With Managing Tail Spend

Managing tail spend in MRO presents unique challenges. First, the decentralized nature of these purchases makes it difficult to track and control spending. Fragmented purchasing across different departments or locations often results in missed opportunities for volume discounts and supplier consolidation. Additionally, the lack of visibility into tail spend can result in inconsistent procurement practices, higher transaction costs, and an increased risk of non-compliance. Without proper management, tail spend can become a barrier to MRO inventory optimization.

Strategies for Effective Tail Spend Management

Effectively managing tail spend requires a strategic approach that includes identifying key areas of spend, leveraging technology, and streamlining supplier relationships.

Identifying and Categorizing Tail Spend

The first step in managing tail spend effectively is to identify and categorize it. This involves analyzing procurement data to pinpoint low-value, high-frequency purchases and understanding their impact on the overall spend. By categorizing tail spend items, organizations can differentiate between essential and non-essential purchases, prioritize areas for improvement, and identify opportunities for cost savings. This data-driven approach enables procurement teams to focus their efforts on the most impactful areas of tail spend.

Leveraging Technology and Automation

Automated procurement systems, powered by AI and machine learning, can streamline the process of identifying, categorizing, and managing tail spend. These systems enable organizations to make informed decisions and enforce procurement policies consistently by offering real-time insights into purchasing patterns. Automation also reduces the administrative burden associated with managing numerous small transactions, freeing up procurement teams to focus on strategic initiatives. Additionally, e-procurement platforms can consolidate tail spend purchases, improving efficiency and reducing the risk of maverick spending.

Consolidating Suppliers and Purchases

One of the most effective strategies for managing tail spend is supplier and purchase consolidation. Simply by reducing the number of suppliers and bundling similar purchases, organizations can negotiate better terms, secure volume discounts, and reduce transaction costs. Since managing fewer suppliers leads to improved relationships, better communication, and increased reliability, supplier consolidation simplifies the procurement process. Additionally, consolidating purchases reduces the complexity of managing tail spend, enabling procurement teams to maintain tighter control over spending and compliance.

Benefits of Deploying Tail Spend Management Solutions

Managing tail spend effectively brings numerous benefits that extend beyond mere cost savings, improving overall procurement efficiency and increased organizational control over spending.

Cost Reduction and Increased Savings

Employing effective tail spend management solutions can result in significant cost reductions and increased savings. By identifying and addressing inefficiencies in low-value purchases, organizations can eliminate wasteful spending, secure better pricing through supplier consolidation, and take advantage of economies of scale. The cumulative impact of these improvements can lead to substantial savings that directly contribute to the bottom line.

Improved Procurement Efficiency

Automation and technology reduce the time and effort required to manage small transactions, allowing procurement teams to operate more efficiently. Consolidating suppliers and standardizing purchasing processes also minimize the administrative workload, reduce errors, and ensure consistency. This increased efficiency frees up resources that can be redirected towards more strategic procurement activities, such as supplier relationship management and long-term cost planning.

Enhanced Visibility and Control Over Spend

Tail spend management enhances visibility and control over an organization’s spending. With a clear understanding of where money is being spent and by whom, procurement teams can enforce policies more effectively, reduce maverick spending, and ensure compliance with corporate guidelines. Enhanced visibility also enables better decision-making, as procurement professionals can identify trends, track performance, and measure the impact of their tail spend management solutions. This level of control not only improves financial accountability but also supports effective MRO inventory optimization.

Manage Tail Spend Efficiently

Effective MRO management is essential for maintaining operational efficiency and reducing costs. Explore our comprehensive guide to learn best practices and strategies that drive results. Use the links below to dive into each critical aspect of MRO inventory optimization.

MRO Data Cleansing

MRO Sourcing

Critical Spare Parts Management

Tail Spend Management