Future Strategies for MRO Inventory Optimization: Building Intelligent, Connected Supply Networks

The next decade of manufacturing competitiveness will be won by organizations that treat MRO not as a cost center, but as a strategic advantage. As supply chains become more connected, digital, and complex, the old model of manual planning, local optimization, and periodic data cleansing is no longer enough.

For global manufacturers running multiple ERP and EAM systems, MRO inventory optimization has evolved beyond managing stock levels – it now demands network-wide intelligence powered by AI, predictive analytics, and real-time visibility.

Here’s how leading Fortune 1000 enterprises are preparing their MRO strategies for the future.

The Shift From Reactive to Predictive MRO

Traditional MRO management is reactive: parts are replaced when they fail, data is cleaned when it becomes unmanageable, and inventory policies are revisited only when budgets tighten.

Future-ready MRO operations flip that model entirely. Using AI-driven analytics and connected data, organizations can now:

- Predict maintenance needs before breakdowns occur.

- Identify excess and at-risk materials in real time.

- Simulate stocking policies using historical consumption patterns.

- Automatically align replenishment with equipment criticality and production schedules.

By moving from reactive to predictive MRO, manufacturers unlock a sustainable cycle of reliability, cost control, and uptime.

Integrating AI Across the Supply Network

For global operations, the real challenge isn’t just optimizing a single plant – it’s aligning hundreds of facilities and thousands of materials across multiple ERPs.

Modern MRO inventory optimization software powered by AI addresses this through:

- Unified data models: Harmonizing data across SAP, Oracle, Maximo, and Infor systems.

- Cross-site visibility: Providing a single, live view of all materials, suppliers, and stock locations.

- Automated recommendations: AI suggests transfers, reorder adjustments, or consolidation opportunities across the network.

- Predictive insights: Continuous learning from real-world usage, downtime, and procurement trends.

This integration creates an agile, intelligent MRO ecosystem – one capable of adapting to disruption, balancing working capital, and maintaining reliability across borders.

Building Resilient, Sustainable MRO Supply Chains

Resilience and sustainability are now board-level priorities. Manufacturers must manage risk while delivering on ESG commitments – and MRO plays a crucial role in both.

Future-ready strategies include:

- Circular inventory models: Reusing or redeploying materials across sites instead of scrapping or overbuying.

- Supplier network optimization: Identifying reliable suppliers that align with sustainability goals.

- Data-driven decision-making: Using AI insights to reduce unnecessary shipments and waste.

- Energy-efficient operations: Ensuring critical spares are available for maintaining optimized, low-energy equipment.

Every decision that improves MRO efficiency reduces carbon footprint and strengthens resilience.

Real-World Example: Top 5 Beverage Manufacturer Drives Global Optimization

A global Top 5 Beverage Manufacturer faced the classic MRO challenge: disconnected systems, excess working capital, and poor visibility across six regional zones. Each region used different data standards, making it impossible to understand where materials overlapped or opportunities existed.

The Challenge

- No visibility across global zones or data types.

- Millions tied up in excess MRO inventory.

- Limited ability to rationalize suppliers or align stocking policies.

The Solution

Verusen implemented its AI-driven MRO inventory optimization platform to unify materials data across all regions. The system delivered real-time visibility into global MRO inventory, allowing the company to standardize stocking policies, eliminate duplication, and predict demand across zones.

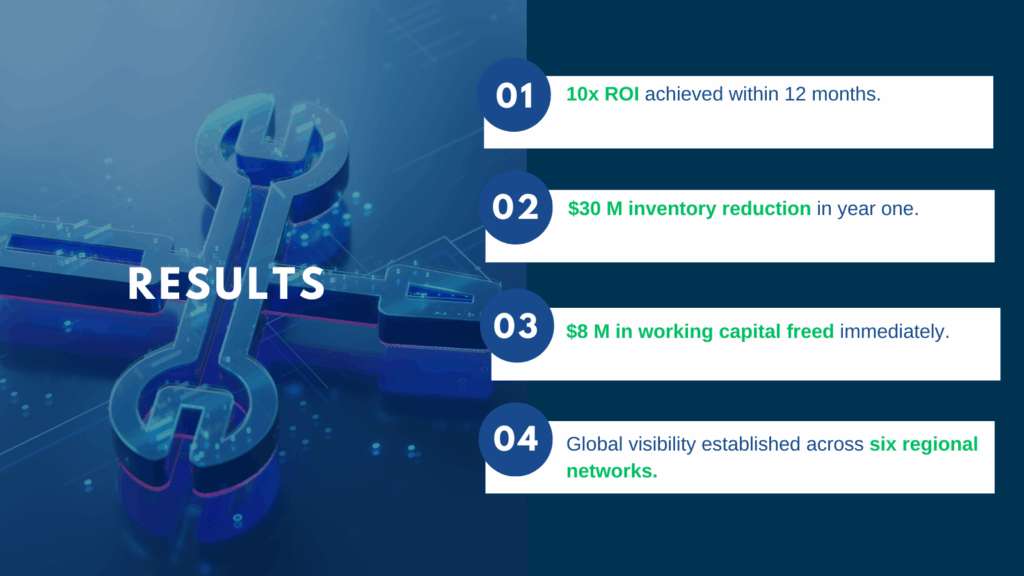

The Outcome

This manufacturer transformed its fragmented inventory landscape into a connected global ecosystem. By aligning people, data, and processes, it not only optimized cost and performance but also advanced its sustainability and supply chain resilience objectives.

What Future-Ready MRO Looks Like

| Traditional MRO | Future-Ready MRO |

| Siloed systems and manual cleanses | Connected, AI-powered data visibility |

| Site-level decisions | Network-level optimization |

| Reactive maintenance | Predictive maintenance, condition-based actions |

| Local supplier sourcing | Global, data-informed supplier strategy |

| Capital tied up in excess stock | Working capital freed for growth |

The future belongs to manufacturers who build intelligent MRO ecosystems – where every spare part, supplier, and decision is connected through a unified platform.

FAQs

How does AI help optimize MRO supply chains?

AI analyzes usage, supplier, and demand data to identify excess, predict shortages, and automate replenishment. It allows global manufacturers to optimize their supply networks continuously rather than through periodic reviews.

Can Verusen integrate with existing ERP systems?

Yes. Verusen integrates directly with SAP, Oracle, Maximo, and Infor, harmonizing data without requiring costly migrations. It acts as an intelligence layer that unifies all materials data.

How can MRO contribute to sustainability?

By eliminating excess stock, optimizing transfers, and improving material utilization, manufacturers can significantly reduce waste and transportation emissions while improving energy efficiency and uptime.

What’s the timeline for achieving results?

Most enterprises begin realizing measurable impact within 6-12 months, with full ROI typically achieved within the first year of implementation.

The future of MRO inventory optimization lies in intelligence, not inventory. By connecting data across systems and regions, manufacturers gain the agility and foresight to act before disruptions occur, reduce waste, and unlock millions in working capital.

Verusen helps global manufacturers build connected, predictive MRO ecosystems.

Request a Global MRO Optimization Consultation today and explore how your organization can turn data into lasting competitive advantage.