How Predictive Stocking Reduces Outages (Without Increasing Inventory)

Stocked Out… Again? It Wasn’t a Supply Problem. It Was a Planning Problem.

You had the part last quarter.

You ordered it twice last year.

Now maintenance needs it – and it’s not there.

The cost? Thousands per hour.

The cause? Planning rules that don’t reflect real-world needs.

Most MRO teams don’t have a stocking problem – they have a prediction problem.

This article is about solving that, using AI.

What You’ll Learn:

- Why MRO stockouts happen even with “optimized” inventory

- The difference between traditional and predictive stocking logic

- How AI forecasts spare part needs without overstocking

- How to align stocking decisions with actual risk and availability

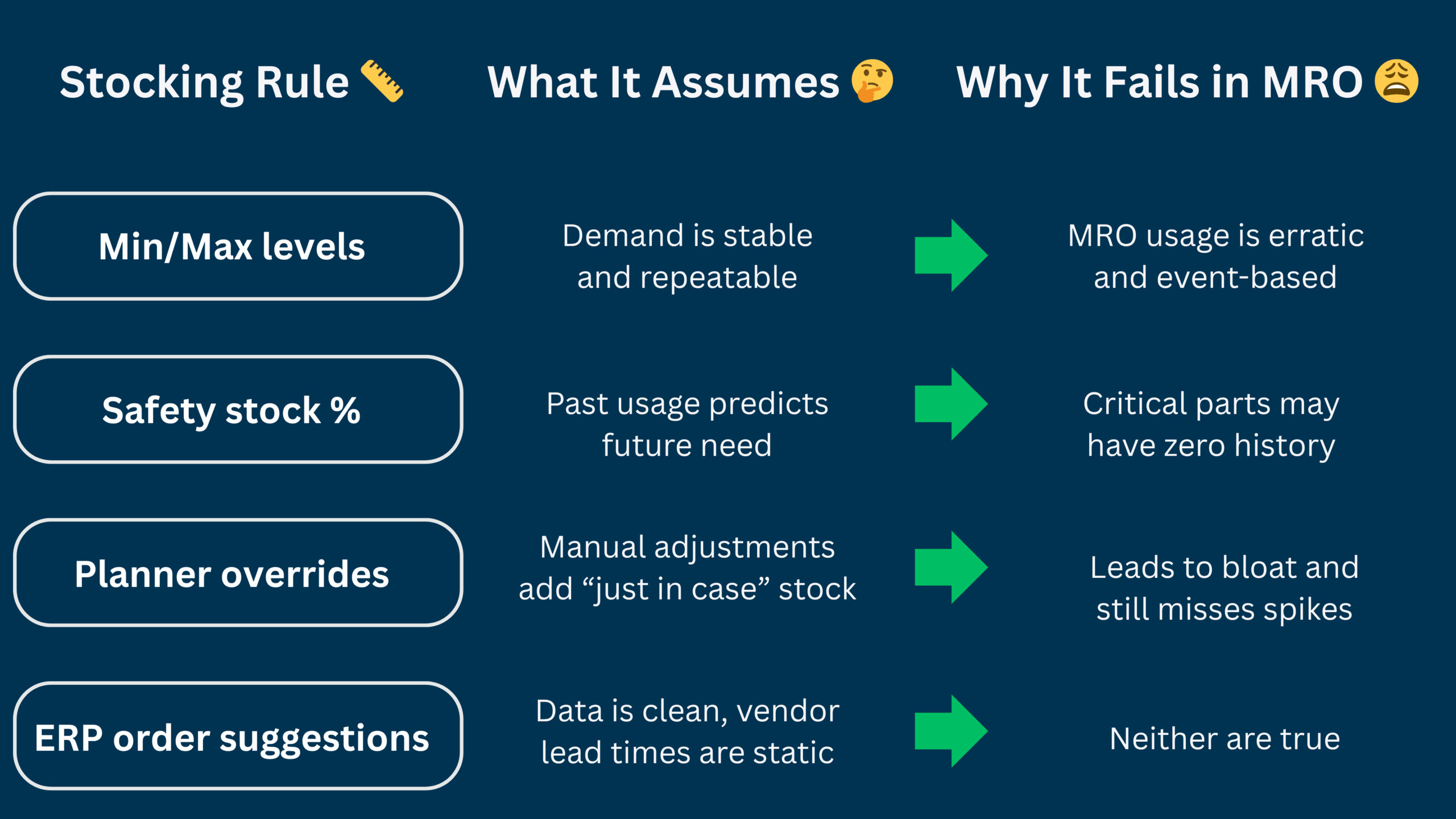

The Problem with Traditional Stocking Logic

- Overstock of non-critical parts

- Understock of essential parts

- Unreliable planning across plants

What Predictive Stocking Really Looks Like

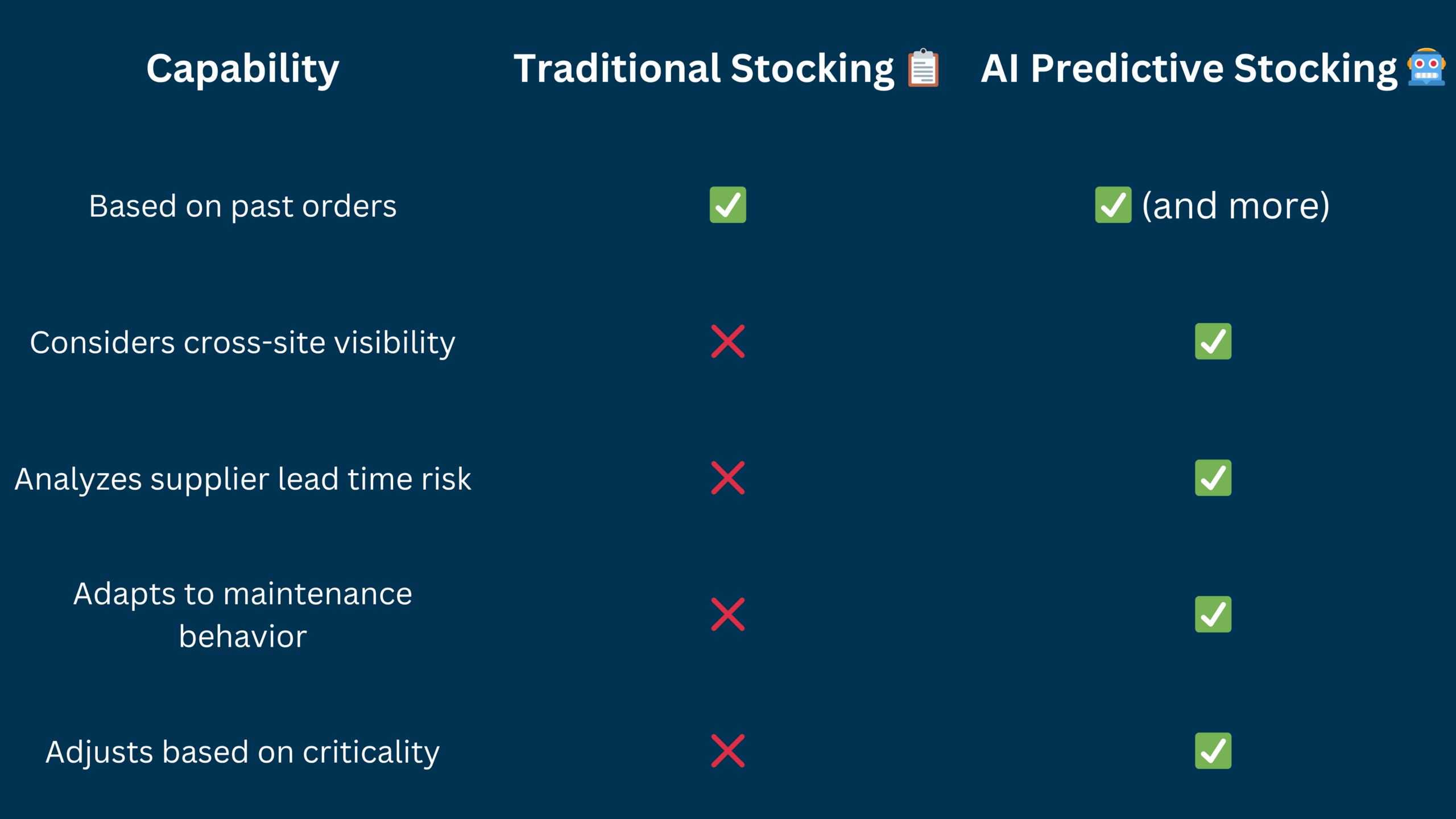

Predictive stocking doesn’t just forecast demand – it forecasts risk.

AI models combine:

- Usage probability: How likely is this part needed soon?

- Criticality scoring: What happens if it’s not available?

- Supplier variability: What’s the chance of delay?

- Cross-site availability: Is the part in another plant right now?

It recommends action based on likelihood and impact, not just reorder thresholds.

Examples of Predictive Actions:

- “Reduce stocking by 40% – demand low, supplier reliable”

- “Reassign from Plant A to Plant B – current surplus, urgent need”

- “Flag part X as critical – usage low, failure cost high, vendor risk rising”

CASE SNAPSHOT: Critical Downtime reduced by Over 90% for Fortune 500 Packaging Manufacturer

Company: Fortune 500 Packaging Manufacturer

Problem:

- $59 million in identified reduction opportunities

- Siloed data caused poor MRO visibility and management

- Unable to locate critical parts, causing downtime threats

Solution:

- Provided full MRO visibility across all facilities.

- Implemented Global Material Search to quickly locate parts.

- Harmonized all MRO data in a single platform.

Results:

- Assets up in 3 days, instead of 4+ weeks.

- Over $1 million saved by minimizing downtime.

- Identified 672 at-risk materials, preventing future stockouts.

What Predictive Stocking Does Differently

Where Predictive Stocking Pays Off Most

- Plants with variable usage patterns

- Distributed operations with similar assets

- Critical spare parts with high downtime cost

- Items with unreliable or long-lead suppliers

- Categories with inconsistent naming or duplication

FAQs

Do I need a clean dataset to start?

No. Verusen’s platform unifies and corrects data at ingestion.

Does this replace our ERP logic?

It overlays and enhances ERP logic – no change to your system required.

How is “confidence” calculated?

Based on AI assessment of usage probability, criticality, supplier behavior, and inventory position.

Ready to Predict, Not React?

We’ll simulate your current stocking rules and show how predictive logic reduces outages and inventory.→ Book a Predictive Stocking Assessment