Inventory Optimization Software: How to Evaluate Vendors (Without Getting Burned)

All Tools Promise Optimization. Only about 3 Deliver. Here’s How to Spot the Difference.

You’ve seen the claims:

“Reduce stockouts!”

“Automate planning!”

“Unlock working capital!”

Every inventory optimization software vendor says they’ll cut costs and improve performance – but when the dashboards go live… nothing changes.

Sound familiar?

Here’s the truth:

- Most inventory optimization tools were built for finished goods, not MRO.

- They optimize by SKU, not by reliability risk.

- They assume clean data. You don’t have that.

This guide will help you spot the difference before your team spends 6 figures on a system that doesn’t fix the problem.

In This Guide:

- The 5 capabilities you absolutely need (and why most vendors miss them)

- How to evaluate optimization logic – not just user interface

- Key questions to ask vendors to shows who’s real

- Why MRO requires a different playbook than production inventory

Most Optimization Software Isn’t Built for MRO

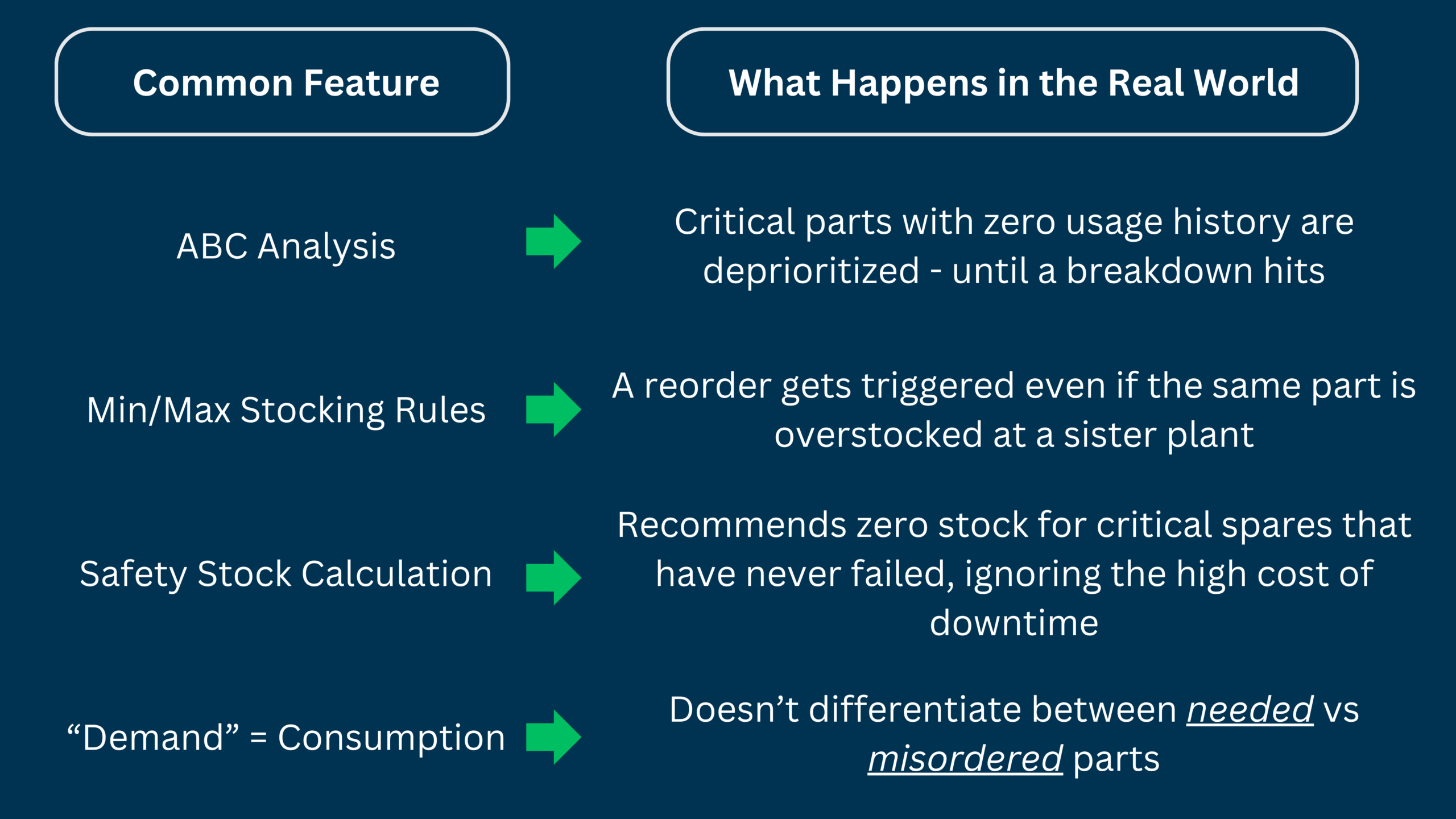

Most optimization software wasn’t designed for low-velocity, high-risk indirect materials. It was designed for finished goods – fast-moving SKUs with clean demand data.

But MRO isn’t that.

It’s fragmented, tribal, and often undocumented. Here’s what that mismatch creates:

Result?

A planner places a $22,000 rush order for a critical valve, unaware that the same part is in stock at a plant four hours away, mislabeled with a different SKU.

Multiply that by 1,000 SKUs across 15 sites, and you’re looking at millions in hidden waste.

This is why MRO inventory needs purpose-built optimization, not just borrowed tools from production supply chains.

What to Look for in MRO Optimization Software

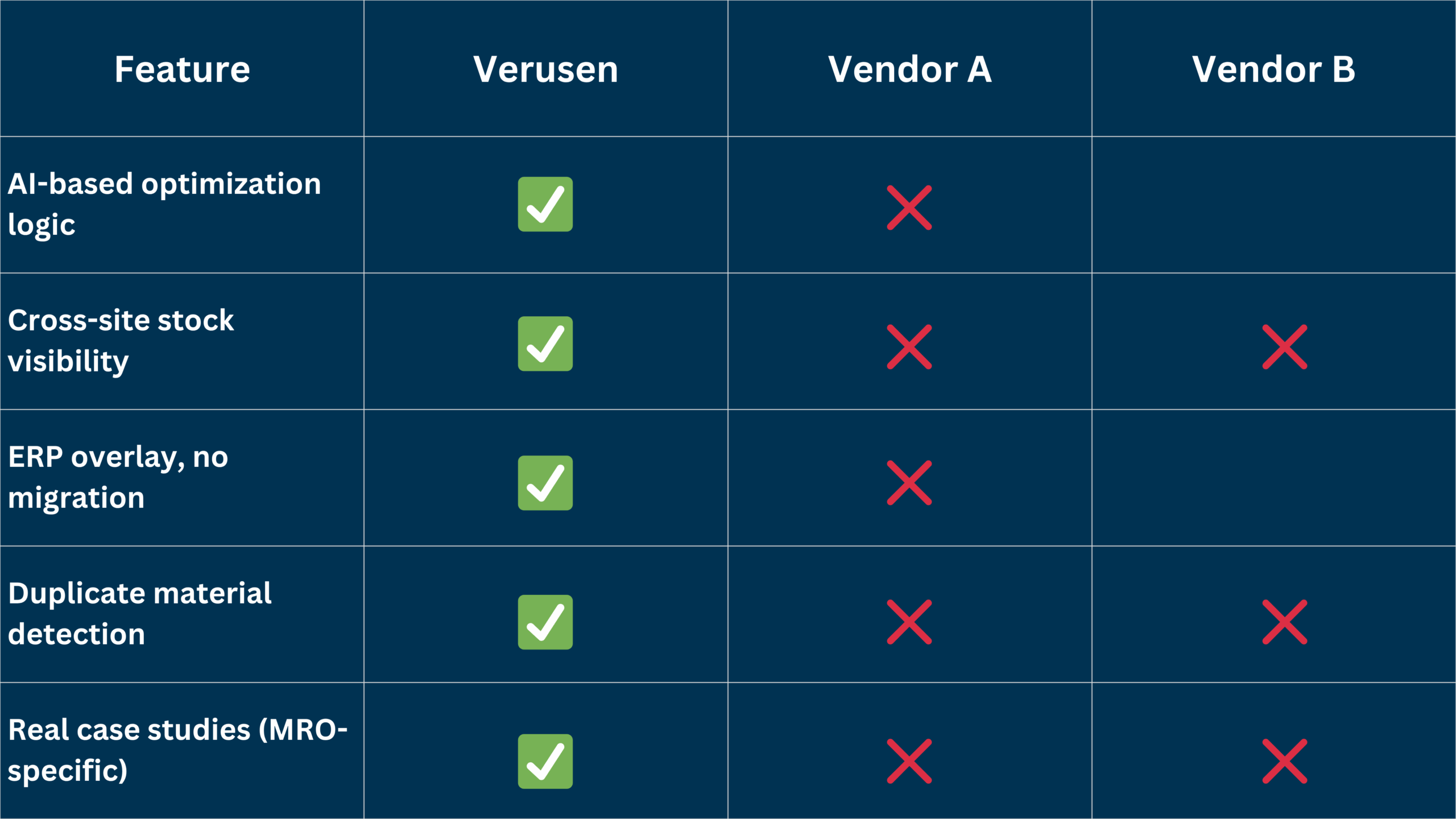

1. Confidence-Based Optimization Logic

Great MRO optimization software doesn’t just flag reorders. It quantifies certainty and exposes why a part needs to be stocked, adjusted, or removed.

Verusen’s AI, for example, calculates a confidence score for every recommendation based on:

- Cleaned + unified part description data

- Supplier lead times and risk classification

- Inventory redundancy across plants

- Usage volatility (e.g., seasonality, one-off events)

- Maintenance criticality tier (is this part tied to uptime?)

This is not just a smarter reorder point.

It’s an actionable insight backed by probability and operational context.

2. Cross-Site Visibility & Virtual Consolidation

Can it show you what’s in stock across all plants, not just locally?

Look for: Multi-site dashboarding, virtual stock views, reorder optimization based on pooled availability

3. AI-Driven Duplicate Detection

If the tool assumes your data is clean, run.

If it fixes duplication without rewrites, you’re in the right place.

Look for: NLP-based part matching, similarity scoring, MRO-specific taxonomies

4. ERP Compatibility Without Migration

You should not need to rip out SAP, Oracle, or Maximo just to gain intelligence.

Look for: Non-invasive overlays, plug-in architecture, clean API exposure

5. Real Proof – Not Just a Demo

Ask for results, not roadmaps.

If they don’t have a customer who looks like you, be wary.

Look for:

- % inventory reduction

- Supplier consolidation metrics

- Time to value (measured in weeks, not quarters)

Vendor Scorecard Example Template

CASE SNAPSHOT: What Good Looks Like

Company: Fortune 500 Packaging Company

Before:

- Siloed data hindered MRO visibility.

- Critical part failures, 4-week downtime threat

- Misaligned teams caused excess inventory

After (with Verusen):

- Unified MRO data, full visibility achieved

- Global search located parts, saved >$1M

- $59M identified savings, reduced downtime risk

7 Questions to Ask Every Vendor

- How do you handle dirty or duplicate MRO data?

- What’s your confidence scoring method?

- Can I see inventory across sites in one view?

- What does your ERP integration look like?

- Do I need to change anything in our ERP?

- Who’s using this in manufacturing/MRO right now?

- What’s your fastest time to value?

FAQs

How fast can I see results?

Most customers see initial optimization insights in under 30 days.

Can we start with a pilot?

Yes. One plant, one product line, or one category. Your call.

Choose Software That Works With Your Chaos – Not Against It

You don’t need a prettier dashboard.

You need a smarter system – one that understands the complexity of MRO, adapts to your reality, and delivers results fast.

→ Book a Comparison Demo with Verusen vs [Your Current Stack]