The Real Cost of Over-Stocking MRO Inventory

Upwards of 28% of Your MRO Inventory May Never Be Used. Here’s What That’s Costing You.

It happens slowly.

One plant buys extra “just in case.”

Another duplicates the order because it wasn’t visible.

Someone else doesn’t trust the ERP, so they over-order manually.

Now your storerooms are filled with parts that haven’t moved in years.

Sound familiar?

If you’re in operations, procurement, or finance, you’re likely sitting on millions in excess inventory. But the real cost isn’t just carrying expense.

It’s invisibility, waste, and risk hiding in plain sight.

In This Article, You’ll Learn:

- The hidden costs of overstocking that most teams miss

- Why MRO overage is so common (even in “optimized” orgs)

- What AI reveals about where you’re leaking money

- How to calculate – and cut – your MRO waste

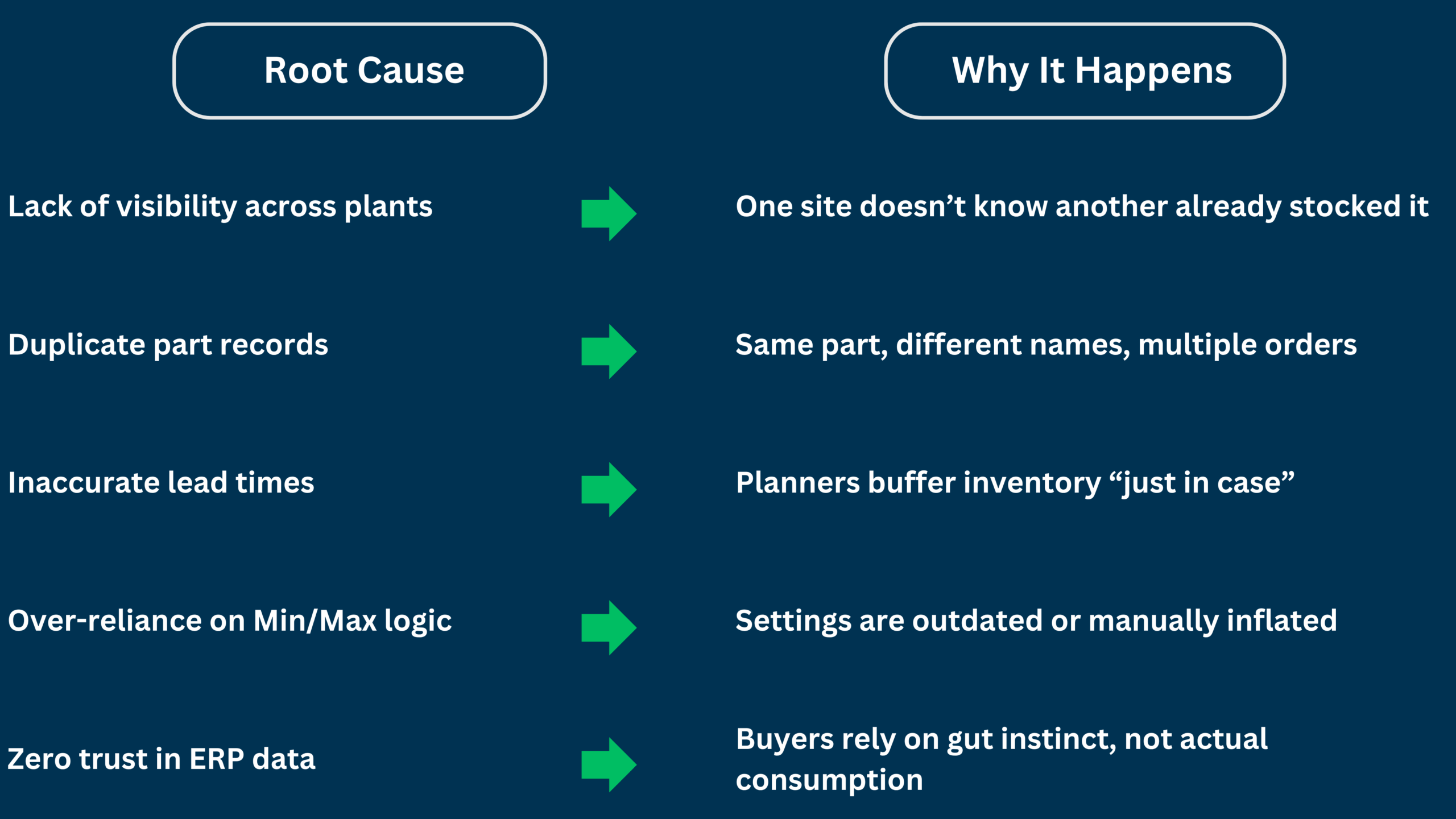

How MRO Over-Stocking Happens (Even in “Efficient” Operations)

Everyone’s doing what they think is safest.

The result? Over $1M+ of MRO stock that may never move.

The Real Cost of Excess MRO Inventory

1. Tied-Up Working Capital

$10M in slow-moving or obsolete MRO?

That’s $10M that could fund CapEx, innovation, or headcount.

Rule of thumb: 15–25% of MRO stock is obsolete or excess in most enterprises.

2. Hidden Supplier Risk

Extra inventory often means more suppliers – fragmented purchasing dilutes leverage and increases delivery variability.

- More vendors = more PO processing = more complexity

- Redundant vendors often hide performance issues

3. Operational Inefficiency

Planners and maintenance teams waste time:

- Searching for parts across systems

- Manually validating what’s already in stock

- Managing space in overflowing storerooms

Time that should go to reliability improvements gets spent fighting spreadsheets.

4. Inventory Write-Offs

Obsolete parts eventually get scrapped – sometimes after years of depreciation.

Your auditors may not catch it now.

But your CFO will when it hits the books next quarter.

CASE SNAPSHOT: $195M Freed from MRO Waste

Company: Global Energy, Oil & Gas Provider

Challenge:

- Unstructured data across regional MRO inventory

- Duplicate materials tying up capital unnecessarily

- Sub-optimal stocking policies & a large amount of SLOB inventory

Solution:

Verusen leveraged existing, un-cleansed MRO data to reduce inventory waste and mitigate operational risk – optimizing stocking levels, facilitating parts sharing, and consolidating duplicate materials.

Results:

- $195M in MRO Inventory Savings Identified

- $102M from Project Materials and SLOB Reduction

- $53.5M from Stocking Policy Optimization

How AI Helps You Cut the Right Inventory – Without Risk

AI models analyze:

- Historical usage by category and criticality

- Cross-site redundancy

- Supplier reliability

- Lead time variability

- Safety risk thresholds

Then they classify inventory:

- High confidence (can reduce)

- Medium confidence (monitor)

- Low confidence (flag for critical review)

This helps you act surgically, not blindly slash stock.

Why Manual Reviews Fail

Manual reviews:

- Take quarters, not weeks

- Are often based on outdated reorder logic

- Lead to pushback from maintenance teams (who don’t trust the process)

AI does this continuously. It shows the “why” – so everyone can act with confidence.

Want to Calculate Your True Overage?

Use this quick formula:

[Total MRO Inventory] × 15% = Estimated Excess

Then add:

Storage cost (5–10%/yr)

Write-off potential

Lost opportunity cost (capital reallocation)

That’s your hidden tax on MRO.

FAQs

How do I know what to cut without risking downtime?

Use AI-based confidence scoring and safety criticality filters. Never cut blind.

Can we reduce inventory without touching our ERP?

Yes. Verusen works on top of your existing systems and shows where reductions are possible.

How fast can we start?

Initial inventory classification and waste identification typically happen in under 30 days.

Want to Know What You Could Cut Without Compromise?

We’ll run a simulation on your current inventory and flag overage by plant, part, or category.

→ Request an Inventory Cost Reduction Assessment

→ Try the Verusen Inventory ROI Calculator (Free)