From Data to Action: AI in MRO Spare Parts Planning

More Data. Still the Wrong Part at the Wrong Time?

You’ve upgraded systems. You’ve invested in BI dashboards. Your ERP says inventory is fine.

And yet…

The critical part is out of stock.

A technician waits 3 days.

Production halts.

So what went wrong?

The answer: your data wasn’t actionable.

And no system – ERP, CMMS, or BI tool – told you what to do next.

This is where AI changes the game.

In This Guide:

- Why traditional planning logic breaks down in MRO

- How AI turns chaotic MRO data into confident stocking decisions

- What predictive parts planning actually looks like

- How to avoid “analysis paralysis” and start acting on what matters

The Problem with Traditional MRO Planning

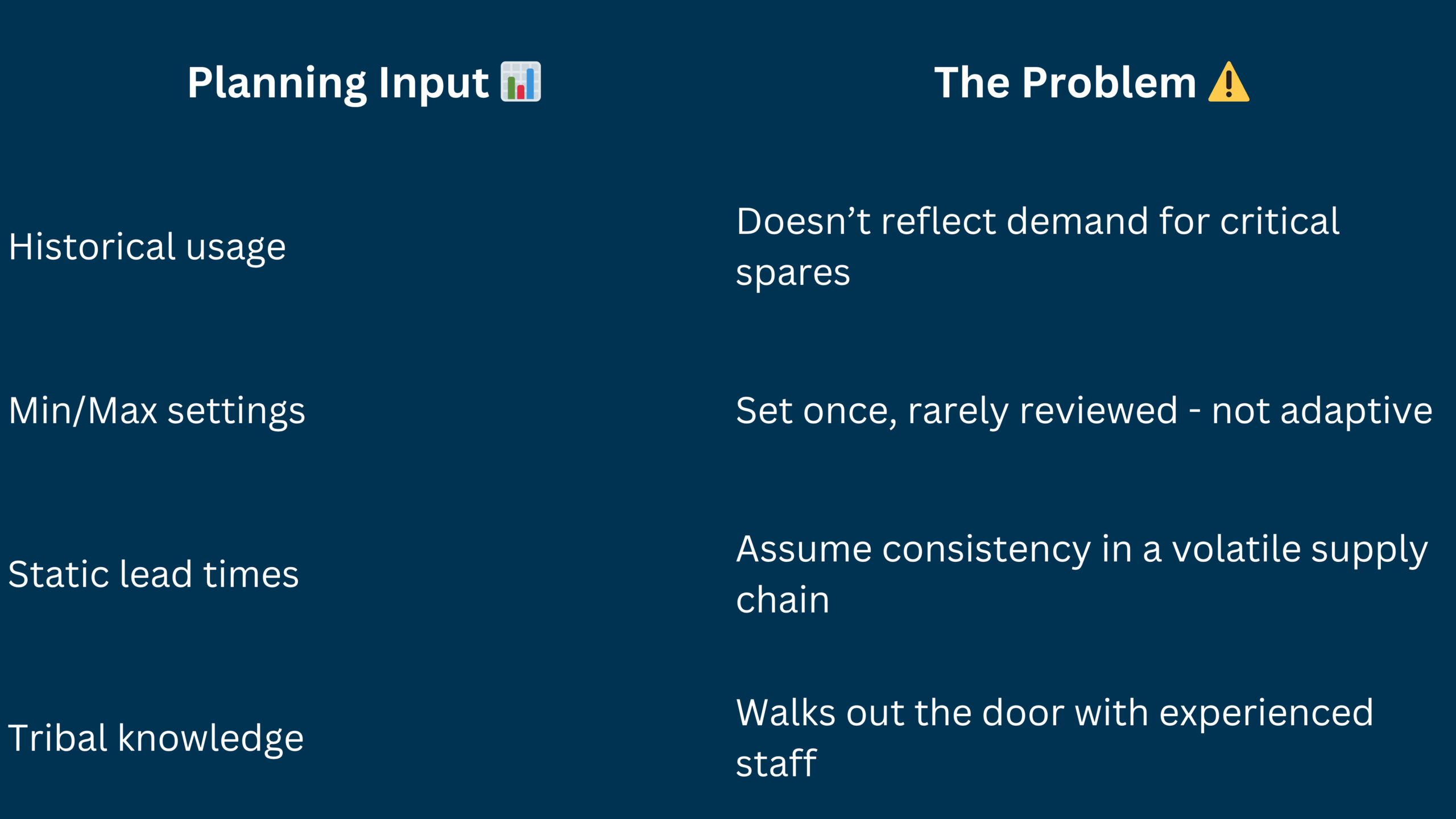

Your planners and buyers work hard. But they’re stuck with broken tools:

The result?

Parts are overstocked “just in case,” or understocked when needed most.

Both cost you in downtime, holding costs, and unplanned purchases.

What AI Does Differently

AI planning doesn’t just count parts. It learns behavior, risks, and context over time.

Verusen’s AI considers:

- Confidence scoring: How likely is it that this part is needed soon?

- Cross-site inventory: Is it already available at another plant?

- Criticality logic: What happens if this part is missing during failure?

- Supplier risk: What’s the probability of delay or substitution?

Instead of “How much should we stock?”, the question becomes:

“What’s the optimal move – reduce, rebalance, or flag for escalation?”

How It Works: From Data to Planning Action

1. Unify Inventory Data Across Systems

Verusen connects to ERP, CMMS, and even spreadsheets to extract MRO data from every site.

2. Clean & Map Materials in Context

AI identifies duplicates, maps similar items, and enriches descriptions – without overwriting ERP records.

3. Apply Predictive Models

Using time-series data + operational metadata, it calculates probability of part need, based on patterns (not guesswork).

4. Recommend Actions

Output isn’t just a dashboard – it’s a playbook:

- “Reduce X by 40% (overstocked across 3 sites)”

- “Transfer Y from Plant A to Plant B (surplus vs shortage)”

- “Flag Z (safety critical, supplier at risk)”

CASE SNAPSHOT: Predictive Stocking in Action

Company: Fortune 500 Energy Producer, 18 Plants

Challenge:

- Inefficient inventory optimization managed in spreadsheets

- Millions in wasted working capital

- Outdated and manual processes to audit part inventory material reviews

Action:

- Verusen unified inventory view across all BU’s

- Transformed processes to effectively complete material reviews

- Delivered actionable insights to achieve more efficient inventory optimization

Result:

- $29.7M in verified savings opportunities

- 45,000 materials reviewed in less than 1 year

- 100% capability to audit all material inventories

Why This Matters to MRO Teams

Planners can’t rely on tribal knowledge forever.

Sourcing can’t act without confidence.

Maintenance can’t tolerate stockouts.

AI empowers every stakeholder to act with precision – using real-time logic, not rules made in a spreadsheet 3 years ago.

Don’t Let BI Dashboards Fool You

Pretty charts don’t prevent downtime.

Insight isn’t the goal.

Action is.

If your software doesn’t show:

- What to reduce

- What to move

- What to escalate

…it’s not helping.

FAQs

Do we have to clean our data first?

No – Verusen’s AI cleans and classifies in-platform. No separate data project needed.

Can we use this with our current ERP?

Yes. It overlays your system and pulls updates regularly.

How long until we see planning insights?

Typically within 30 days of onboarding.

Want to Go From Reactive to Predictive?

We’ll review your current planning logic and show you the top opportunities to cut cost and risk – in one report.→ Book a Predictive Planning Demo