How a Fortune 500 CPG company went from scattered MRO data across sites to unified visibility, resulting in $14M verified savings and $59M optimization opportunity

- Challenge: Disconnected ERPs, lack of insight across regions

- Solution: AI harmonized inventory data across global zones

- Outcome: $14M realized savings; $59M opportunity identified

4 Minutes

Average time spent reviewing material recommendations

$14M

Verified savings realized

$59M

Working capital optimization opportunity

672

At-risk materials identified

Our Client

A Fortune 500 CPG company with operations across the globe.

Key Business Needs

- Company has grown through multiple acquisitions

- Consolidating MRO data into a single location instead of multiple, disparate ERPs

- Reducing working capital across all sites is top priority

- Reduce duplicate inventory and spend across business units

- Easily locate parts and materials with an easy to use tool

- Drive consistency in inventory management & process across all sites

Business Challenge

- Visibility into materials inventory across disparate systems and data types

- Creating organizational alignment

- Improving asset reliability

- Increasing productivity

- Driving cost savings

Solution

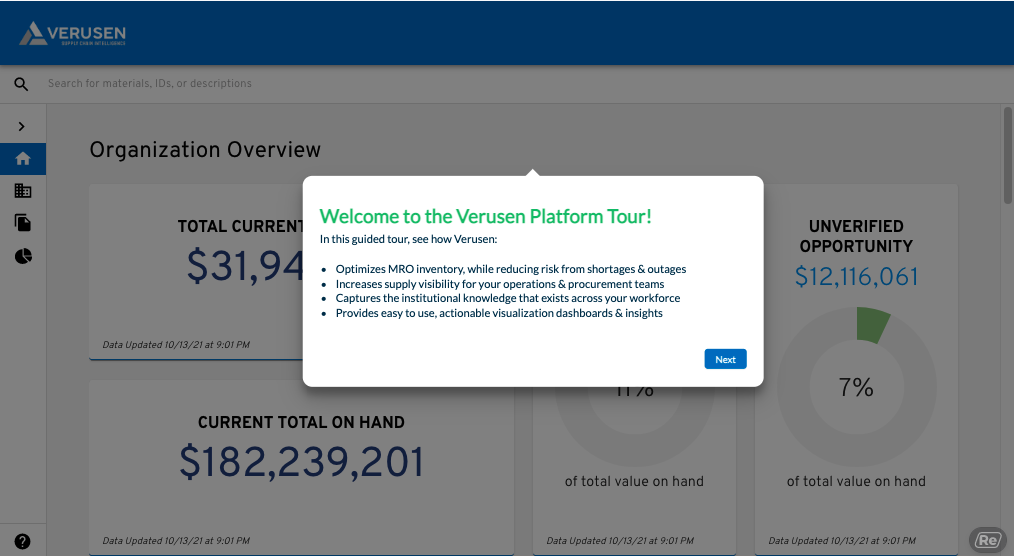

With the Verusen solution, our client gained the visibility they needed to better understand their MRO materials across multiple global sites, enabling them to drive organizational alignment and engineered reliability.

The identification of cost saving and cost avoidance opportunities allowed this client to more strategically purchase materials without risking production uptime.

Watch This 3 Minute Demo to Learn More