How AI Identifies Duplicate MRO Materials Across Complex Enterprises

What Are Duplicate MRO Materials?

Duplicate MRO materials occur when the same physical part is recorded multiple times across ERP or plant systems under different SKUs or descriptions. This inflates inventory, drives unnecessary procurement, and hides stock availability.

Takeaway: Eliminating duplicate MRO materials can free up millions in working capital and prevent costly stockouts for asset-intensive industries like mining, oil & gas, chemicals, packaging, automotive, and energy.

Why Duplicate MRO Materials Are So Persistent

Why do manufacturers struggle with duplicate MRO parts?

- Siloed Data: Multiple ERP instances (SAP, Oracle, Maximo, Infor) across plants create fragmented visibility.

- Inconsistent Naming: Free text, regional variations, and vendor inconsistencies make parts appear unique.

- ERP Limitations: ERPs require exact matches – a single character difference prevents detection.

- Manual Review Bottlenecks: Master Data teams can’t manually clean 400k+ SKUs across global operations.

How AI Identifies Duplicate Materials

What makes AI better than ERP reports?

AI goes beyond exact matching. It analyzes language, specs, and vendor data using NLP and machine learning, spotting hidden duplicates that humans and ERPs miss.

Step-by-Step: How AI Deduplication Works

- Aggregate data from multiple ERP/EAM systems

- Normalize attributes (unit of measure, vendor codes)

- Apply NLP models to identify linguistic variations

- Score duplicates with confidence levels

- User validation strengthens accuracy over time

Unique Advantages

- Identifies duplicates with messy, incomplete data

- Generates confidence scores instead of yes/no matches

- Learns and adapts to your company’s naming conventions

Enterprise Impact of Deduplication

- Working Capital Savings: Fewer SKUs mean lower carrying costs.

- Procurement Efficiency: Consolidated spend strengthens supplier leverage.

- Reduced Downtime: Identifying stock already available prevents delays.

- Data Quality: Clean material masters improve ERP performance.

Try Verusen’s free MRO Data Health Check to see how much duplication may be hiding in your system.

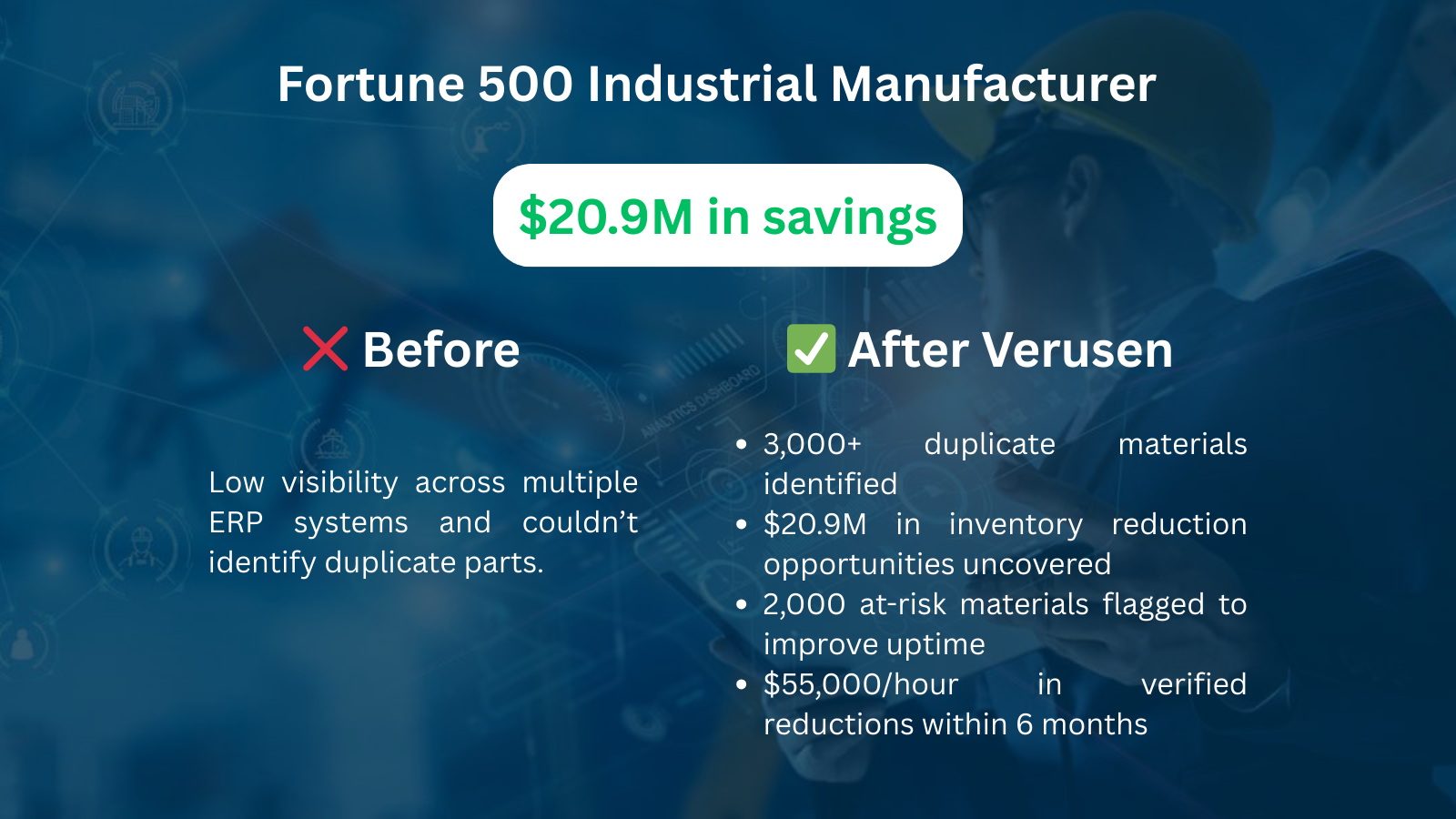

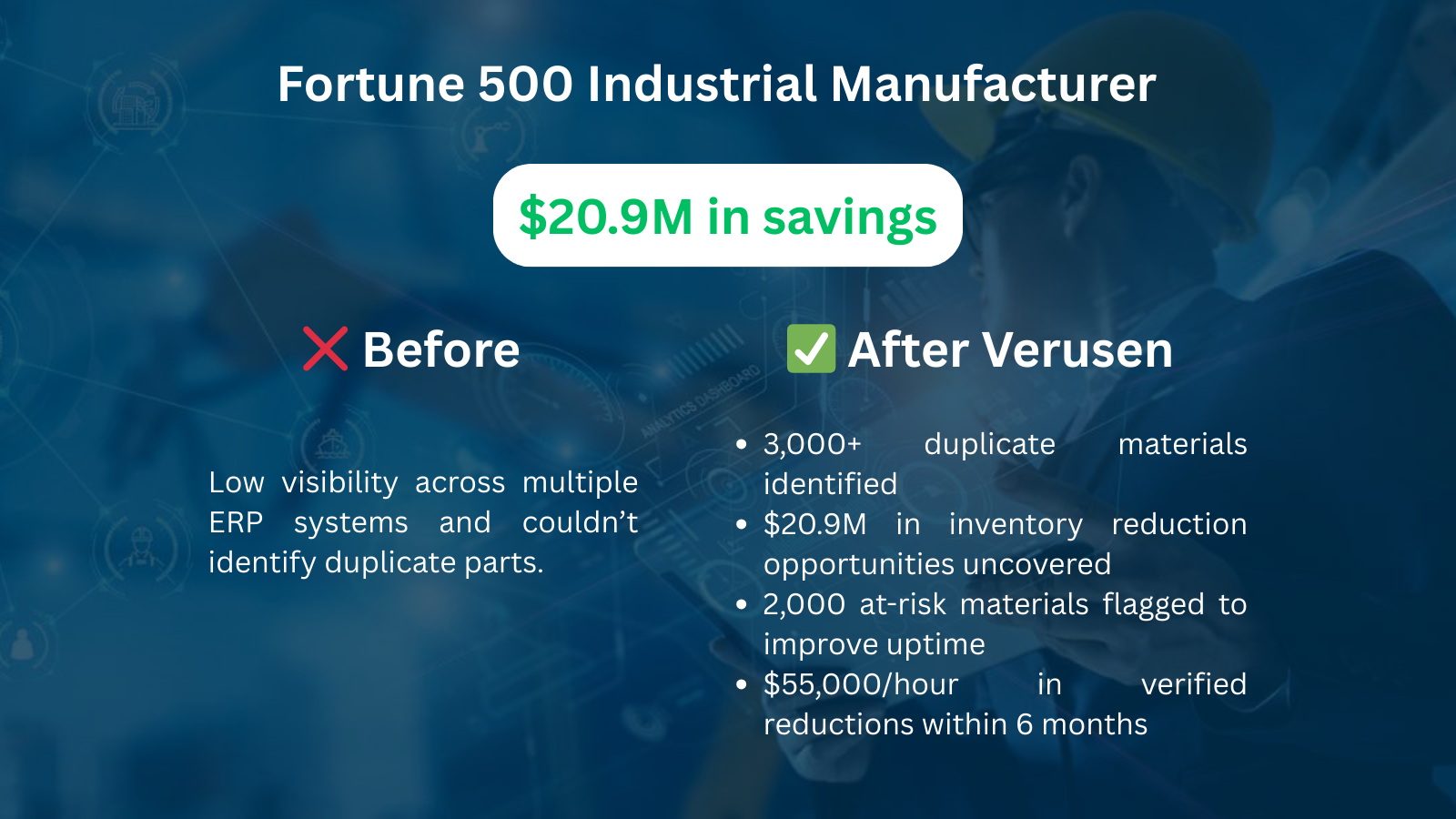

Fortune 500 Industrial Equipment Manufacturer saved $20.9M

Proof Point: This was achieved without replacing their ERP, by layering Verusen onto existing systems.

FAQs on MRO Data Cleansing and Deduplication

What is MRO data cleansing?

MRO data cleansing is the process of standardizing, correcting, and removing duplicate records from material master data to improve accuracy and usability. For industries like oil & gas and chemicals, this ensures critical spares are always visible.

How does AI improve duplicate material detection?

AI uses machine learning and NLP to identify hidden duplicates across multiple ERP systems, even when names, units, or descriptions differ. This is essential in automotive, mining, and packaging, where uptime is mission-critical.

How fast can duplicates be identified?

Most enterprises see high-confidence duplicate matches within 30-60 days of implementation, even in complex multi-site operations.

Do we need clean data first?

No. Verusen’s AI works directly on messy, inconsistent data and delivers actionable insights without upfront cleansing.

What’s the ROI of eliminating duplicates?

Enterprises typically achieve 10-20% reductions in MRO inventory and multi-million-dollar savings in working capital – proven in industries like energy, drilling, and large-scale manufacturing.

Key Takeaways

- Duplicate MRO parts silently waste millions and create risk across large enterprises.

- AI-driven deduplication identifies duplicates in weeks, not years, even with messy ERP data.

- Real-world results include $20.9M in verified opportunities and major uptime protection.

Conclusion

Duplicate materials are draining capital and creating operational blind spots. AI delivers a fast, scalable way to surface these inefficiencies and unlock millions in value without overhauling ERP systems.

Book a call today to uncover the hidden cost of duplicate MRO materials in your own enterprise.