The Ultimate Guide to AI-Powered MRO Optimization

Two Identical Parts. Two Different SKUs. One Big Problem.

You walk into a storeroom and see rows of bins, each labeled differently, each holding the same exact bearing. One was ordered last month. One was ordered last year. One’s from a supplier you haven’t used in 18 months.

That’s MRO inventory today: bloated, fragmented, invisible.

And most teams don’t even know how much of it they’re overstocking – or how often they’re buying things they already have.

This Guide Will Show You:

- Why MRO inventory “optimization” often isn’t

- How AI identifies the invisible waste in your storerooms

- What real-world results look like – and how fast you can get there

- How to choose the right optimization path (with or without ERP changes)

The Truth Most ERP Dashboards Won’t Tell You

Here’s the reality: most companies are holding 20–30% more MRO inventory than they need.

Not because they want to.

Not because of bad sourcing.

But because they don’t know what they already have.

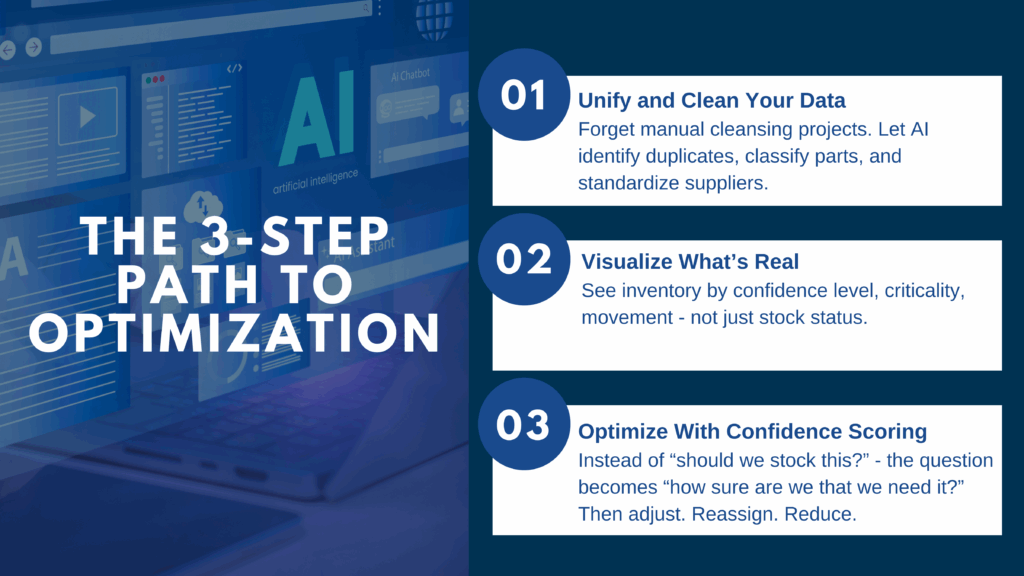

That’s where AI-driven optimization comes in.

It doesn’t start with reorder points or min/max logic.

It starts by seeing the truth in your data, across sites, suppliers, and systems.

What Is MRO Inventory Optimization?

MRO (Maintenance, Repair, and Operations) inventory optimization is the process of ensuring the right spare parts are available at the right time, without overstocking or understocking.

But here’s the problem:

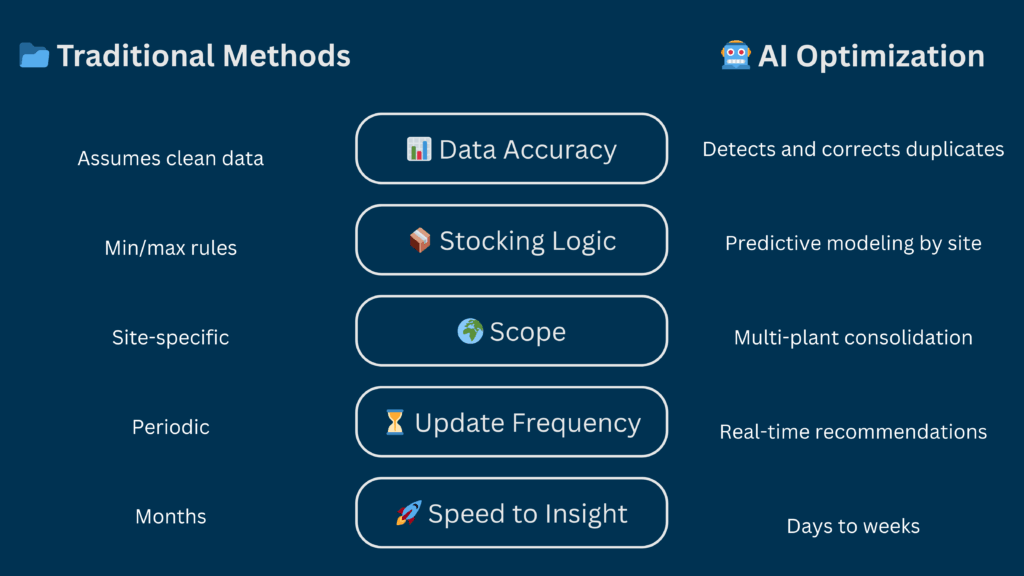

Traditional tools treat MRO like any other inventory category.

They rely on historic demand. They assume your data is clean. They optimize in isolation.

In reality, your plants aren’t linear. And your data isn’t clean.

That’s why your “optimized” inventory still feels overstuffed – and yet never enough.

Why It Matters Now

- Working capital is tied up in parts you might never use

- Downtime costs climb when the “right part” is in the wrong location

- Supply chain volatility exposes every blind spot in your spare parts logic

Your CFO wants reductions.

Your plants want reliability.

Your ERP says everything is fine.

You’re stuck in the middle – until you change how you see your MRO data.

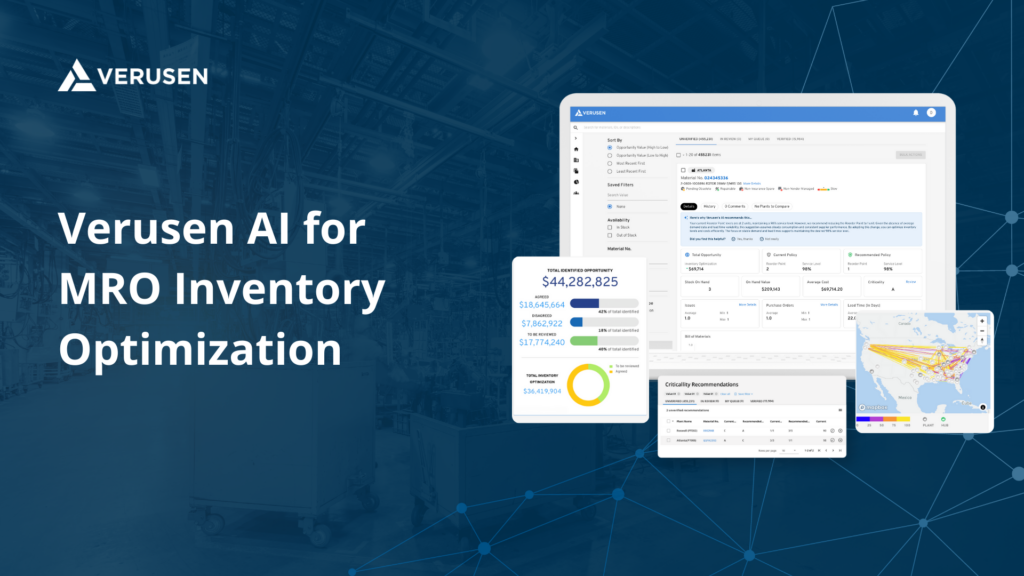

Traditional Methods vs. AI Optimization

Legacy tools give you safety stock.

AI gives you confidence-based stock, based on what’s really happening, not just what’s recorded.

CASE STUDY: $195 million in MRO Inventory Savings Opportunities

Client: Global Energy, Oil & Gas Provider

Problem: Unstructured data across MRO inventory, duplicate materials, sub-optimal stocking policies.

Solution: Implemented Verusen AI to utilize existing MRO inventory data, effectively balancing risk inventory reduction.

Results:

- $102 million savings from Project Materials & SLOB (Slow-Moving and Obsolete) Reduction

- $53.5 million savings from Stocking Policy Optimization

- $15 million savings from Carrying Costs, Warehouse Reductions

3 Common Mistakes to Avoid

Most optimization fails before it begins – because the foundation (your data) is broken.

FAQs

What is MRO inventory optimization?

It’s the strategic reduction of excess, risk-mitigated parts stock using predictive tools, not static spreadsheets.

How is AI used in MRO optimization?

AI unifies data across plants, finds duplicates, and recommends stocking levels based on probability models.

Do I need to replace my ERP to use this?

No. Verusen overlays your existing systems – and starts showing insights in weeks, not quarters.

Want to See What You’re Sitting On?

We’ll analyze your current MRO inventory and show you the top opportunities to reduce overstock – without putting uptime at risk.→ Request a Tailored Inventory Assessment

Or try the Inventory Cost Calculator to see your potential savings in under 2 minutes.