How a top food & beverage manufacturer went from fragmented MRO control to regional visibility, resulting in $30M optimization and 8× ROI in under a year

- Challenge: No regional MRO visibility, inefficient spend across zones

- Solution: AI-driven harmonization across 6 regions with single view platform

- Outcome: $30M optimization opportunity; 8× ROI delivered in under 12 months

$30M

Global Working Capital Optimization Opportunity in 24-36 months

8X

Return On Investment in < 1 year

$2M

Verified Inventory Reduction opportunity in less than 90 days

$1M

Working capital reduction in < 1 year

Our Client

A top 10 CPG company with global operations in over 10 countries.

Key Business Needs

- Extend beyond BI and integrate actionable insights into operations

- Find solutions to improve maintenance performance and time to resolution

- Improve the quality of inventory data for their internal data catalog

- Reduce duplicate spend across business units

- Drive consistency in inventory management & process across all regions

Business Challenge

- Visibility into materials inventory across disparate systems and data types

- Creating organizational alignment

- Improving asset reliability

- Increasing productivity

- Driving cost savings

Solution

With the Verusen solution, our client gained the visibility they needed to better understand their MRO materials across 6 global zones, enabling them to drive organizational alignment and engineered reliability.

The identification of cost saving and cost avoidance opportunities allowed this client to more strategically purchase materials without risking production uptime.

The identification of cost saving and cost avoidance opportunities allowed this client to more strategically purchase materials without risking production uptime.

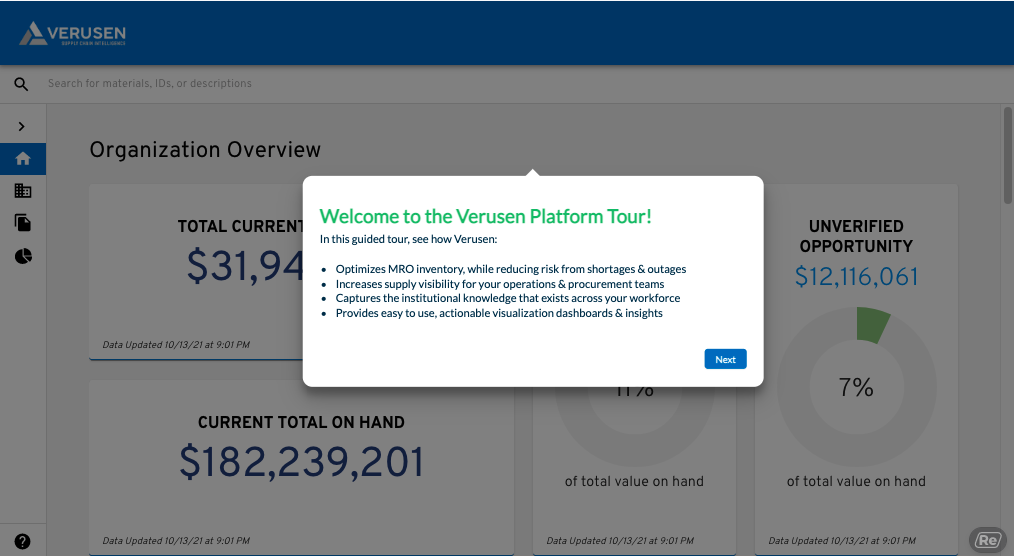

Watch This 3 Minute Demo to Learn More

"

“Verusen created our intelligent, self-learning materials management solution to transform our future supply network.“

- Top 10 Energy Supply Chain Executive