Spare Parts Network Sharing

Optimize Spare Parts Inventory

with Real-Time Demand Visibility

Challenges of Siloed Data & Inventory

Most organizations rely on systems that are not built to help them optimize sharing of MRO/spare parts inventory across locations. This inability leads organizations to overstocking, which ties up capital, understocking, which risks expensive downtime, and overall inefficient operations.

Increased Costs

& Tied-Up Working Capital

To prevent longer unplanned downtimes, facilities carry higher spare parts inventory levels than necessary to ensure parts are available when needed. This overstocking ties up capital in slow moving or obsolete materials.

Materials Unavailable

for Unplanned Downtime

When a machine goes down, long supplier lead times and quickly finding the right parts across facilities become a major challenge—especially with inconsistent labeling.

Inefficient Demand

Planning

Without a clear understanding of demand across facilities, procurement and sourcing teams struggle to identify where supply optimization is needed most.

An Always-On Approach to Sharing Spare Parts

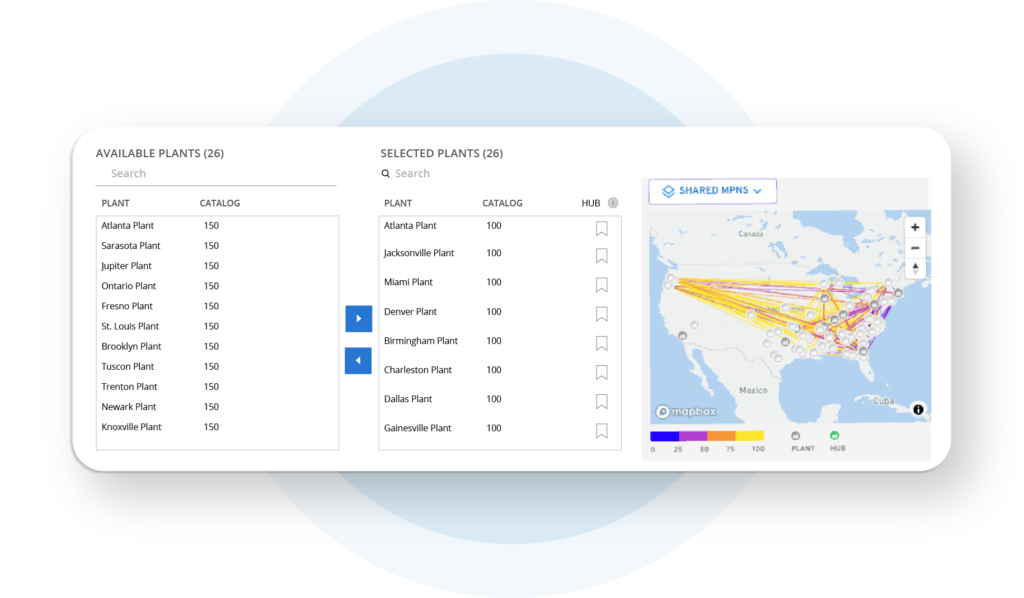

Easily identifying opportunities for part sharing allows procurement teams to optimize supply across facilities. Our AI-driven Spare Parts Network Sharing helps you eliminate excess materials while ensuring critical parts are always available at the right place and time.

Our AI Platform

Builds custom sharing networks

to support inventory sharing across facilities based on specific sites, materials, or geographic regions.

Optimizes hub & spoke networks

by leveraging purpose-built AI to analyze material overlap across facilities, enabling strategic reallocation and right-sizing of inventory levels for improved efficiency and cost savings.

Offers effortless material planning

eliminating months of manual analysis by instantly identifying shareable materials and ideal stock levels at each facility.

What's In ItFor You

Share your spare parts inventory and facilitate transfers across networks to optimize your supply chain to ensure efficient resource utilization and improves overall operational effectiveness.

Minimize Cost & Capital

Sharing excess parts between facilities prevents unnecessary purchases. Centralized inventory visibility across networks enables spare parts transfers where they are needed most, reduces redundant orders and frees up working capital.

Trust in Material Availability

Even with lower inventory levels, network optimization modeling will ensure that critical parts are readily accessible if needed. This balanced inventory approach is built on aligned criticality of materials.

Accurate Demand Planning

Understanding network demand enables efficient planning. A shared inventory approach enhances demand analytics, improving forecasting accuracy and purchasing decisions. This leads to optimized resource allocation and a more agile supply chain aligned with actual demand.

Transform Your MRO Supply Chain

No spreadsheets or data extraction to manually optimize supply across facilities. Our always-on AI provides visibility to MRO materials across all your facilities and the sharing opportunities associated with them.

Continuous, Automated, Always-On AI

Verusen’s AI platform uses advanced natural language processing (NLP) to tackle MRO inventory challenges. With over 20 million SKUs ingested, it enables immediate optimization without the need for data cleansing or third-party assistance, utilizing your existing data as-is.

Frequently AskedQuestions

Most Verusen customers are fully operational within 45 days from the time we receive the initial data transfer.

Typically, customer resources dedicate just 2-4 hours per week during the onboarding process. This is significantly less than what is required with traditional SaaS solutions, which often demand upwards of 30 hours from IT teams.

Verusen integrates seamlessly with a wide range of ERP, EAM, and P2P systems, using our comprehensive suite of certified, optional connectors to provide the insights and results you need.

Verusen doesn’t use seat licenses, so you get unlimited access for all relevant team members. Admins, chosen by you, can easily grant access to anyone in your organization who needs it.