Supply Chain Optimization Built for Pulp and Paper Manufacturing

MRO Optimization is Key for Working Capital Reduction, Inventory Control and Preventing Stock Outs

Pulp and paper companies like yours understand the importance of MRO inventory management. Unfortunately, you often have to focus on working capital reduction over optimization initiatives. Balancing these efforts leads to one falling through the cracks, while the other feels like a constant uphill battle. Whether you’re a pulp mill, paper mill, or converter facility, you’re constantly working with large equipment that requires a vast inventory of spare parts that turn over quickly.

Leveraging a partner like Verusen helps you streamline MRO materials management by automating inventory management strategies, from inventory data consolidation to risk reduction, all while optimizing cash flow savings

Download our ebook "5 Reasons Why Companies Struggle with MRO Optimization" to gain key insights and solidify your MRO strategy

Simple | Configurable | Sustainable

Resiliency +Reliability

Downtime caused by manual spare parts management can be catastrophic, effects that not only impact your internal operations, but also trickle down to your customers. Having an accurate account of spare MRO parts is essential for pulp and paper companies to assess, strategize, and mitigate shortages or unexpected deficiencies. Vast distribution networks, from pulp mills to converters, add additional complexities to MRO inventory management. Having purpose-built technology to support these processes has never been more relevant.

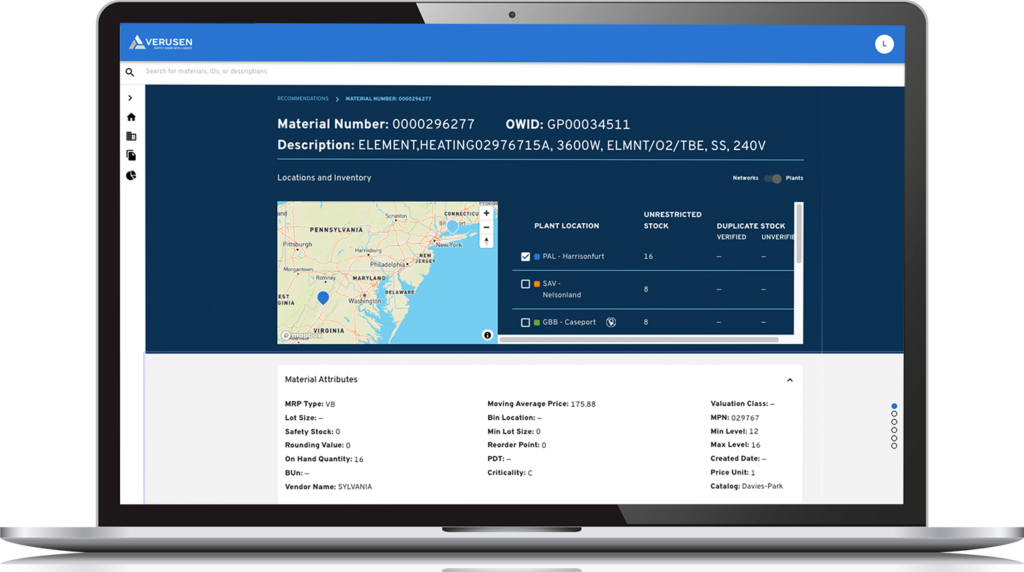

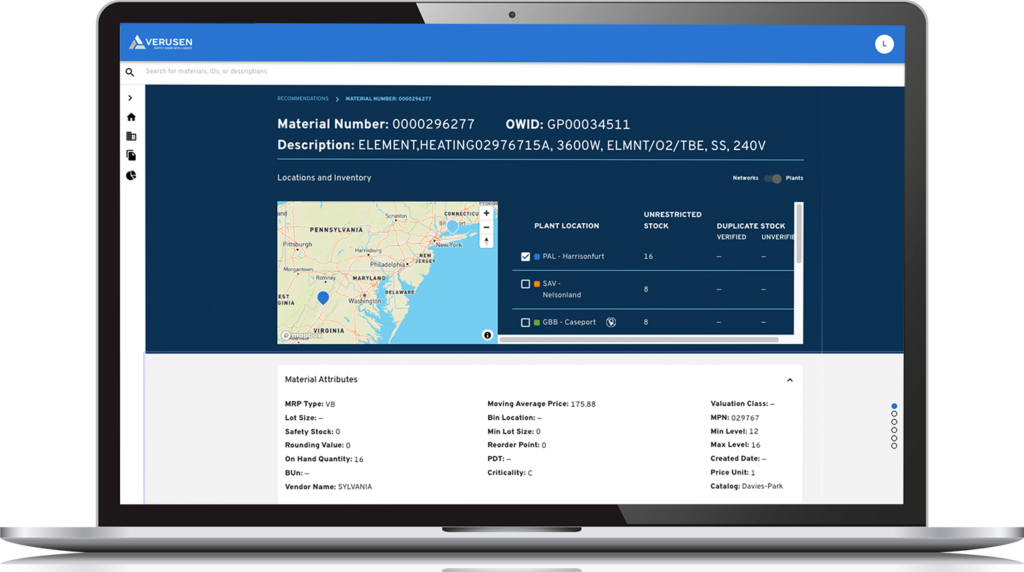

Using Verusen’s AI-based materials intelligence platform enables data harmonization across multiple systems and locations and ensures that when an inevitable problem occurs, you know you have the supplies to resolve it.

CostOptimization

Balancing risk while driving down costs is easier said than done, especially if you lack the right technology and processes. Converting sites, for example, turn parts slower than their paper mill counterparts, meaning excess inventory costs more to store and manage and could be transferred to other sites for greater efficiency. However, these optimization opportunities generally fall on the backburner without the visibility an inventory management tool like Verusen Trusted Material provides.

GrowthEnablement

Mergers and acquisitions are common scaling and cost saving strategies that enable manufacturers to increase market share, create longevity, and increase revenue and profitability. Unfortunately, M&A activity can significantly disrupt workflows and often take year to successfully migrate all necessary components into the larger organization.

During this transition, MRO and spare parts inventory management can slip through the cracks and severely handicap synergy in your M&A strategy. Avoid costly downtime and manual processes when you implement a material management solution like Verusen.