Use Case | MRO Inventory Optimization | Mining Enterprise Cut $20M in Inventory Waste

How a leading mining enterprise went from fragmented MRO data to unified visibility, resulting in 10-20% working capital reduction and $20M in savings.

- Challenge: Disparate ERP/EAM systems, limited visibility

- Solution: Verusen’s AI unified data across sites-no data cleanse required

- Outcome: 10-20% working capital reduction; ~$20M cost avoidance

10-20%

Average working capital reduction

$20M

Average cost avoidance/savings

2-3X

Guranteed return on inventment

30 Days

Kick-off Length (no data cleanse!)

What improvement you can expect for your Mining Business:

- Average of 10-20% of working capital reduction

- Consolidating MRO data into a single location instead of multiple, disparate ERPs/EAMs

- Optimizing working capital across all sites while reducing downtime

- Reduce excess inventory and spend across project sites

- Easily locate parts and materials with an easy to use tool

- Drive consistency in MRO inventory procurement & management processes

- 90 day onboarding using existing MRO inventory data

Common Industry Challenges

- Assets constantly exposed to tough conditions

- Increasing prices and inconsistent lead times

- Labor and asset-intensive projects spread across multiple geographies

- Short window times for fulfilling maintenance requirements

- Constant change of technology requirements

- Pressured to reduce costs without disrupting production

Verusen's Approach to MRO Inventory Optimization

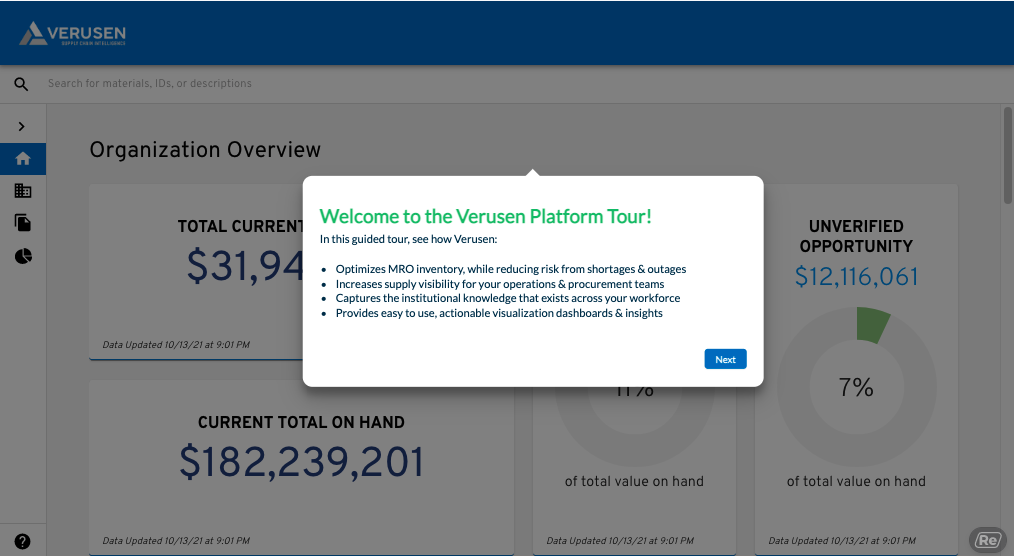

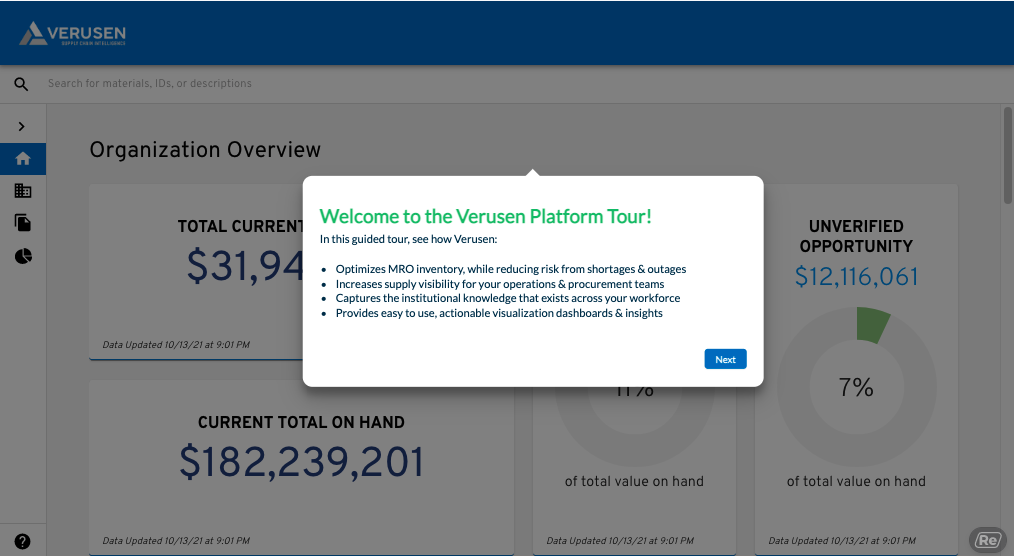

Verusen’s purpose-built MRO inventory optmization solution allows customers to gain true visibility into their MRO materials amd asset spares across multiple global sites. The AI-powered plaftorm enables them to drive organizational alignment and engineered reliability using their existing MRO inventory data “as is,” eliminating the need for a traditional data cleanse to achieve unmatched results.

The identification of cost saving and cost avoidance opportunities allows customers to more strategically purchase materials, establish material criticality prioritization, and reduce the risk of production downtime.

Watch This 3 Minute Demo to Learn More